Turntable Slew Ring - China Manufacturers, Factory, Suppliers

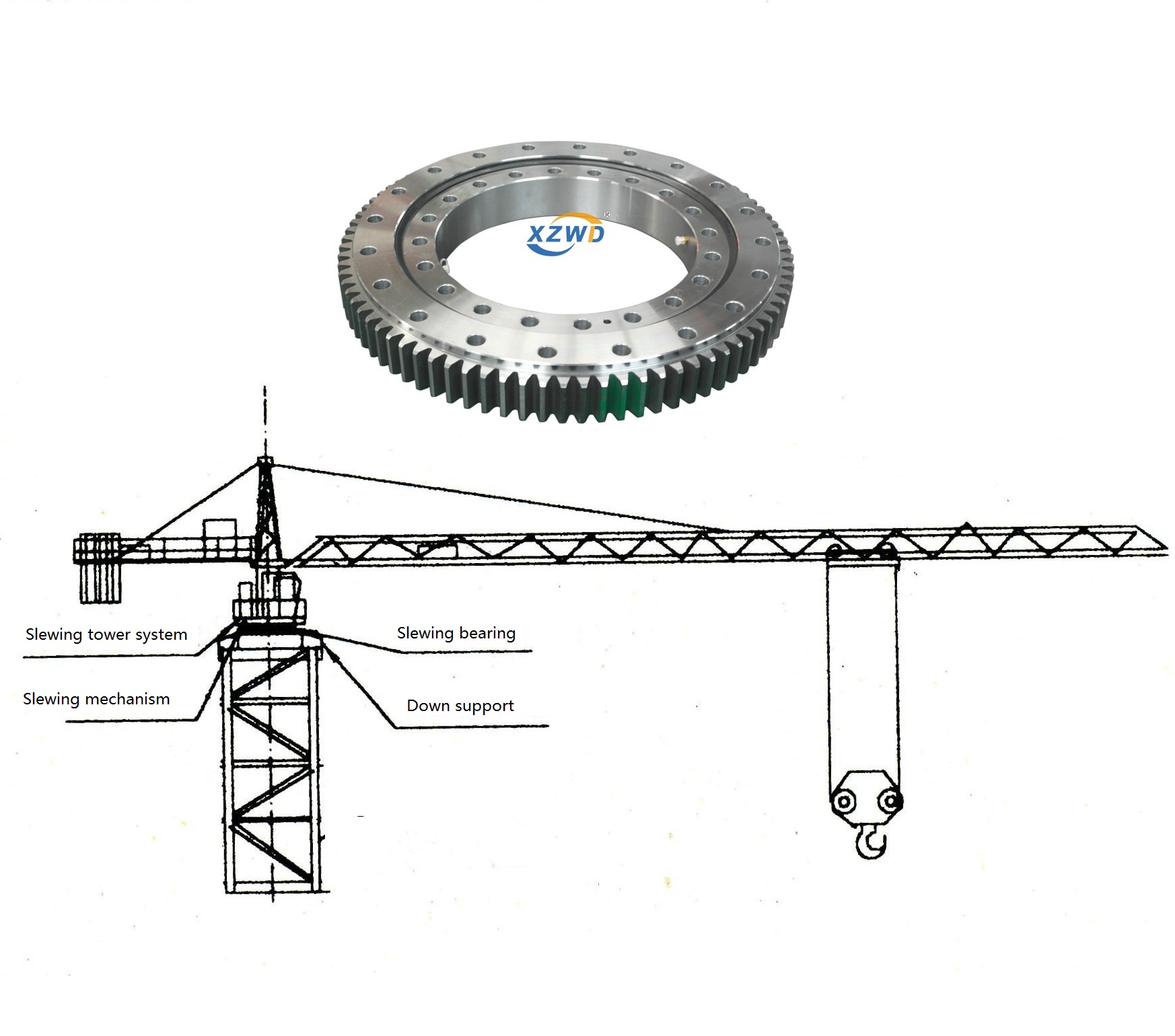

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of Turntable Slew Ring, Slewing Drive Manufacturer, Single Row Slewing Bearing, slewing drive,Slewing Excavator. We have four leading products. Our products are best sold not only in the Chinese market, but also welcomed in the international market. The product will supply to all over the world, such as Europe, America, Australia,Berlin, Lesotho,Paris, Vancouver.Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

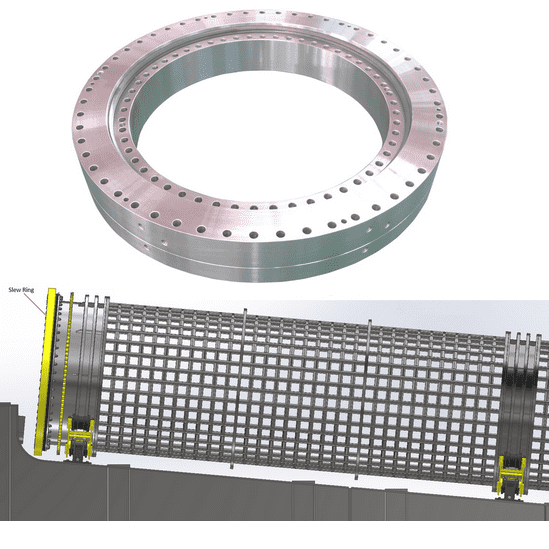

Related Products