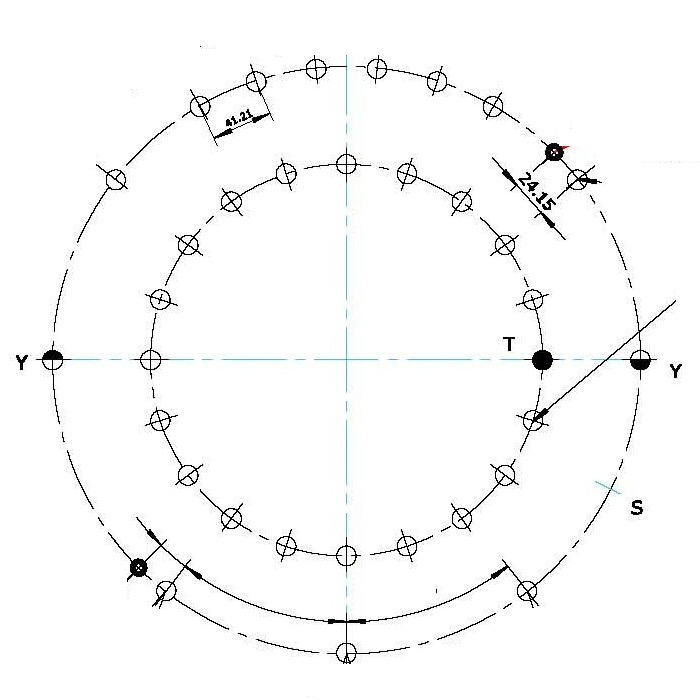

Factory supply replacement 330/340 slewing ring turntable bearing

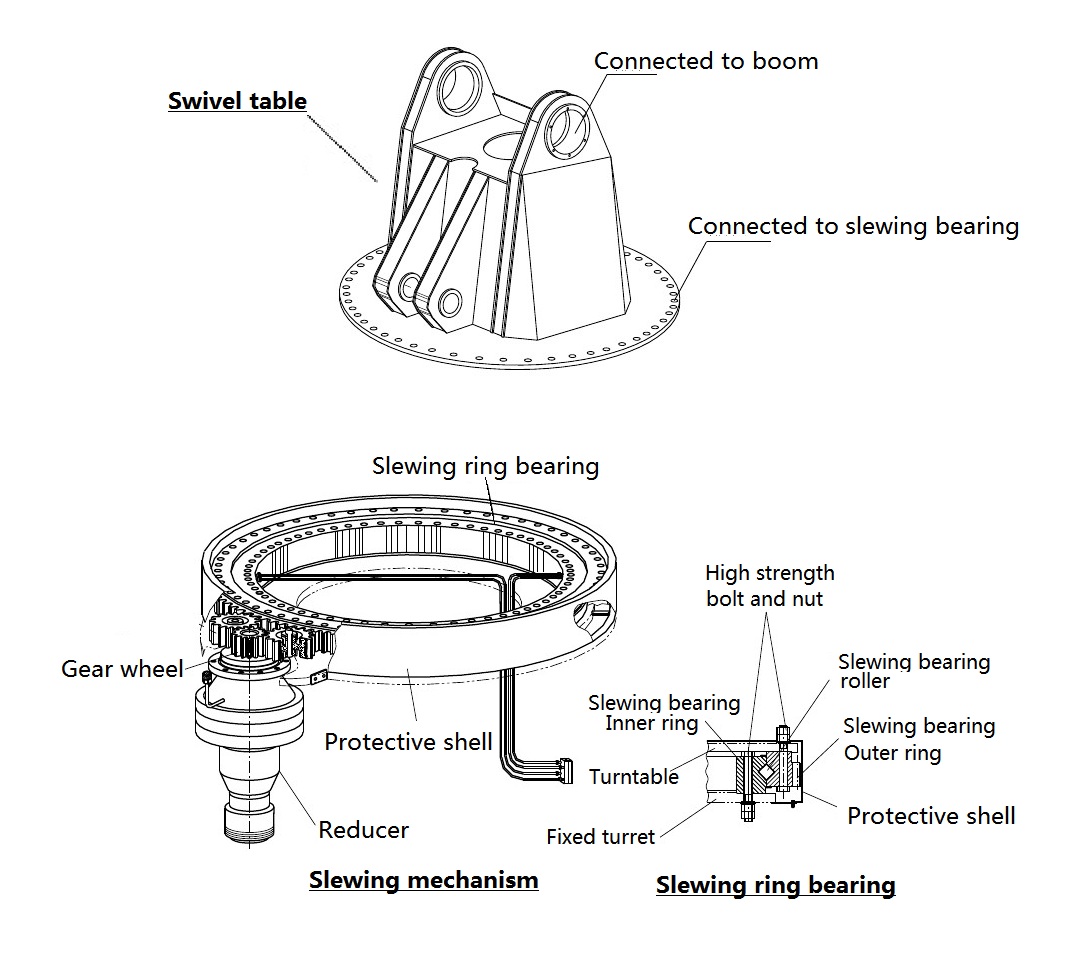

Truck crane is a kind of crane installed on the chassis of ordinary car or special car. Its driving cab and lifting cab are set separately. The advantages of this kind of crane are good mobility and rapid transfer. The main part of crane is slewing mechanism. The slewing mechanism is mainly composed of slewing bearing and power system.

How to maintain slewing bearing of truck crane?

1. Visually inspect the bolts on slewing bearing before each crane operation or at least once a week;

2. After the slewing bearing starts to work for 100 hours, check whether the bolts are loose, and check again after 300 hours; Then check every 500 working hours.

3. The slewing bearing shall be filled with lithium grease before installation;

4. When replacing the bolt, wipe the bolt clean, apply thread fastening glue and then tighten it.

XZWD slewing bearing is a professional manufacturer of slewing bearings, which can provide various types of slewing bearings. If UNIC 330 slewing rings are required, please contact us and we will provide drawings.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.