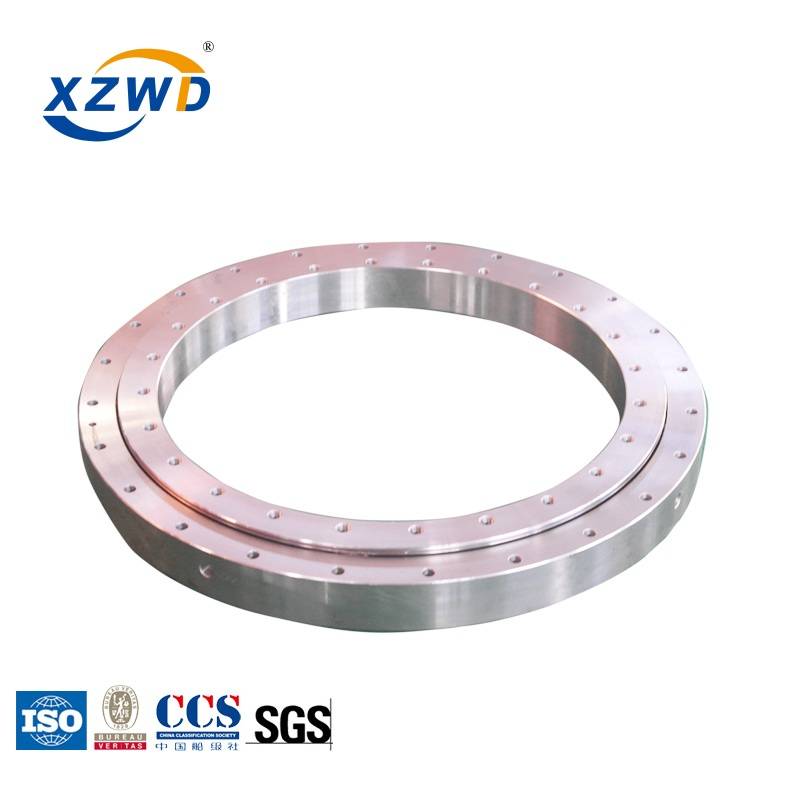

Excavator Turntable Bearing - China Manufacturers, Factory, Suppliers

"Based on domestic market and expand overseas business" is our development strategy for Excavator Turntable Bearing, Slewing Rotary Bearing, Kmi Slew Drives, Cross Roller Ring Bearing,Slew Drive For Solar Tracking System. Winning customers' trust is the gold key to our success! If you are interested in our products, please feel free to visit our web site or contact us. The product will supply to all over the world, such as Europe, America, Australia,Russia, Brasilia,Adelaide, Italy.Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

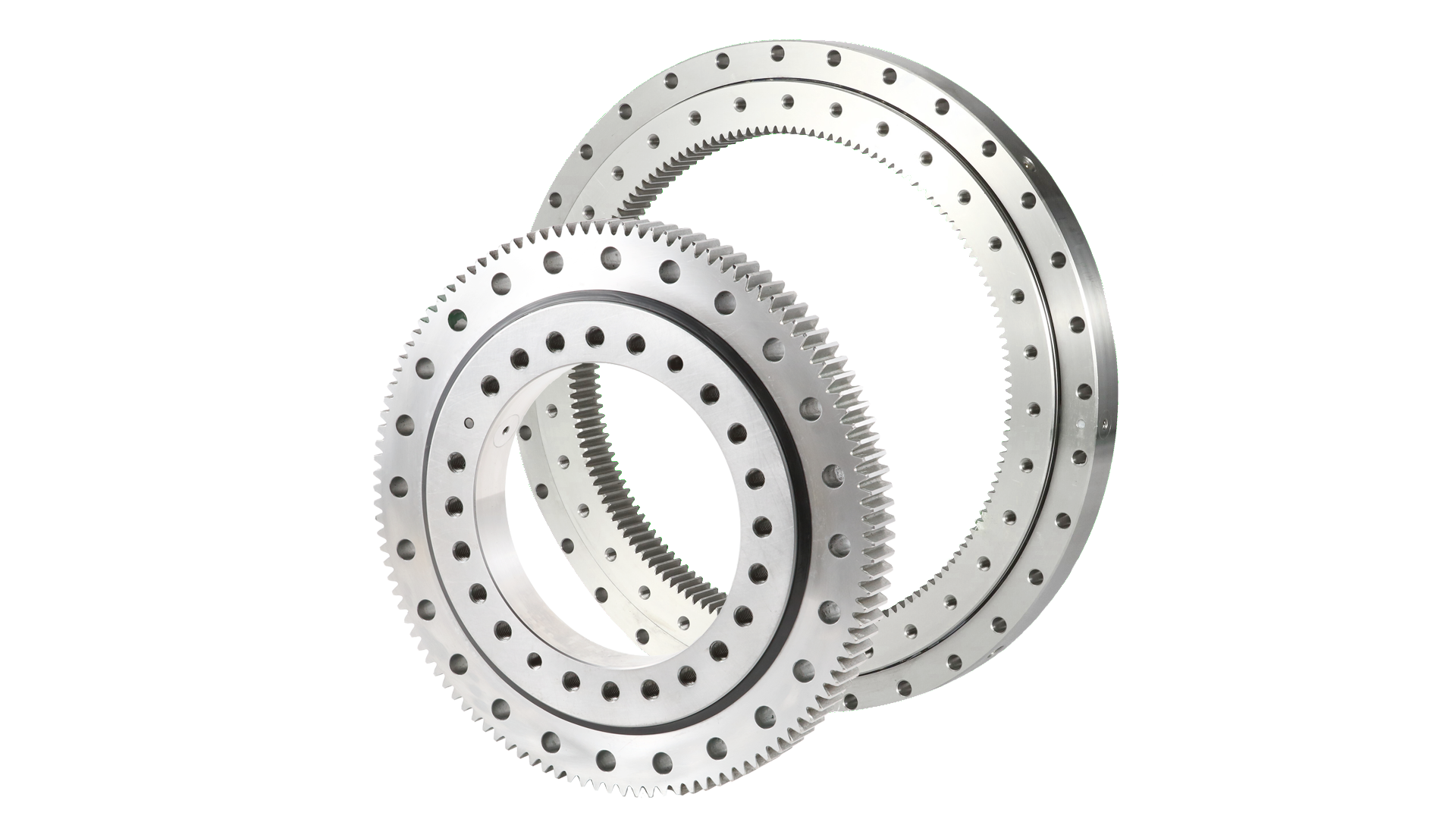

Related Products