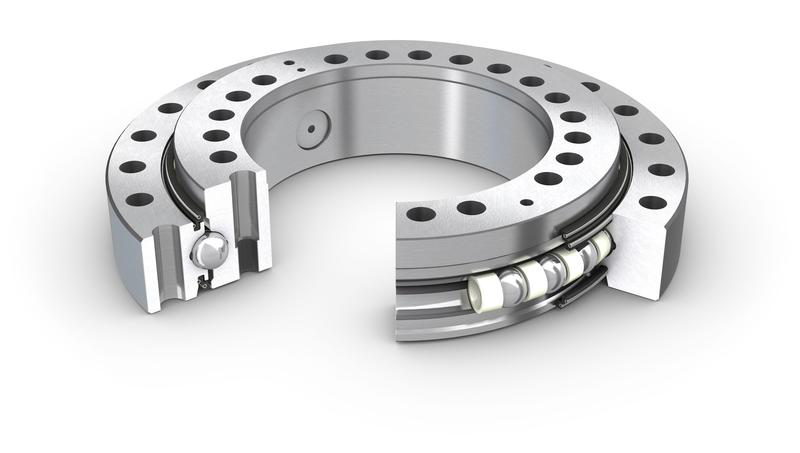

The slewing ring bearing is mainly composed of an upper ring, a lower ring and a full complement ball. The entire design of the slewing ring is used for rotating solutions at low speeds and light loads. The two single-row and double-row designs, as well as the convenience of pre-drilled mounting holes.

In real life of slewing bearing, the weight difference of cold blanking can be controlled at 1%, the collapse depth is 0.5mm, the end face inclination is less than 2°30, and the weight difference for hot blanking is within 2%, and the end face is inclined The degree is less than 3°.

Constrain the shearing die, that is, to restrict the warpage, axial movement, and cut flattening of the bar by radial tightening. Some of these methods are tightened only at the fixed knife end, and some are tightened at both the fixed knife end and the movable knife end. The tightening methods include cylinder type and mechanism linkage.

The slewing bearing is a representative rolling bearing with a wide range of uses. It is used for high-speed or even extremely high-speed operation and is very durable. This type of bearing has low friction, high limit speed, simple structure, low cost, and easy to achieve high manufacturing accuracy.

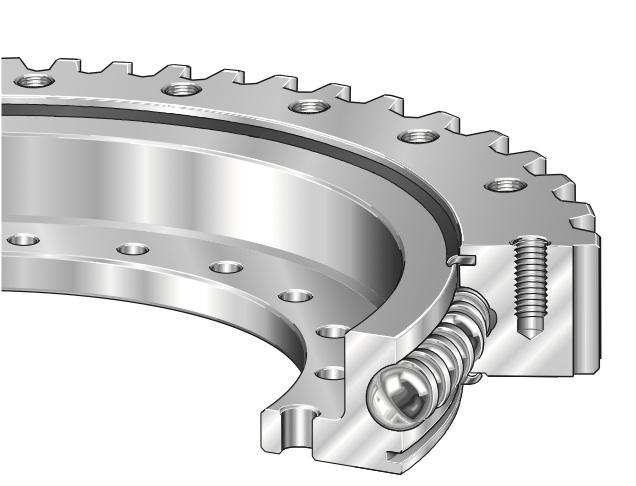

The slewing ring bearing also has a certain degree of centering ability. When it is inclined 10 degrees relative to the housing hole, it still works normally, but it has a certain impact on the life of the bearing. Slewing ring bearing cages are mostly stamped steel plate corrugated cages, and large bearings are mostly car-made metal solid cages. The seal of the slewing ring bearing is to prevent the filled grease from leaking out on the one hand, and on the other hand to prevent external dust, impurities and moisture from entering the inside of the bearing and affecting normal operation.

Since most slewing bearings work under heavy load and low speed, the sealing type of the bearing adopts two structures: rubber seal ring seal and labyrinth seal. The rubber seal ring seal itself has a simple structure. It has been widely used due to its small space occupation and reliable sealing performance. However, its shortcoming is that the rubber sealing lip is prone to early ageing at high temperature and loses its sealing performance. Therefore, the slewing ring bearing that works under high temperature conditions is suitable Use labyrinth seal.

Post time: Mar-26-2021