XZWD| Window cleaner used slewing ring bearing

Window cleaner used slewing ring bearing

In the past, for cleaning of high-rise buildings, large rope hanging boards were generally used for manual cleaning, which was unsafe and uncivilized. With the continuous improvement, manual cleaning of large rope hangers will eventually be banned, and window cleaners are the safest, practical and efficient special equipment for high-altitude operations.

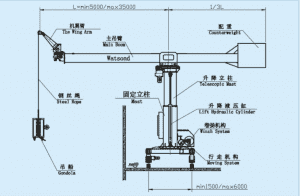

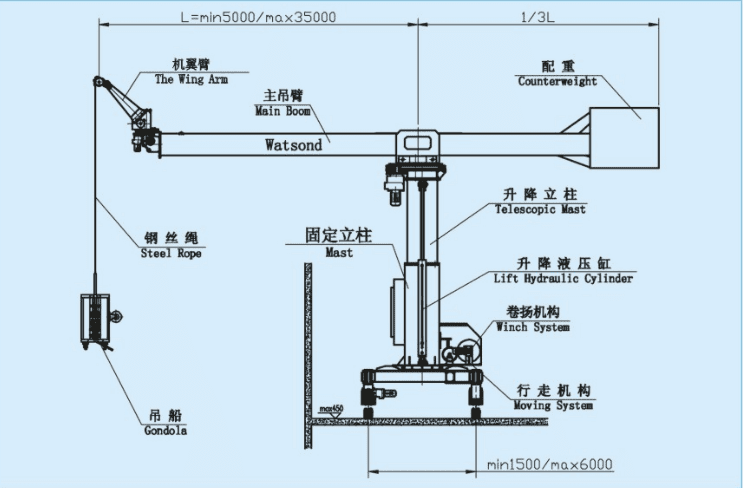

The rotation of the boom is composed of a slewing bearing and a motor reducer. When the motor rotates, the reducer gear drives the slewing bearing to rotate and the boom immediately rotates. The motor uses a brake motor and a track-type window cleaner. When the power is cut off, the drive immediately stops.

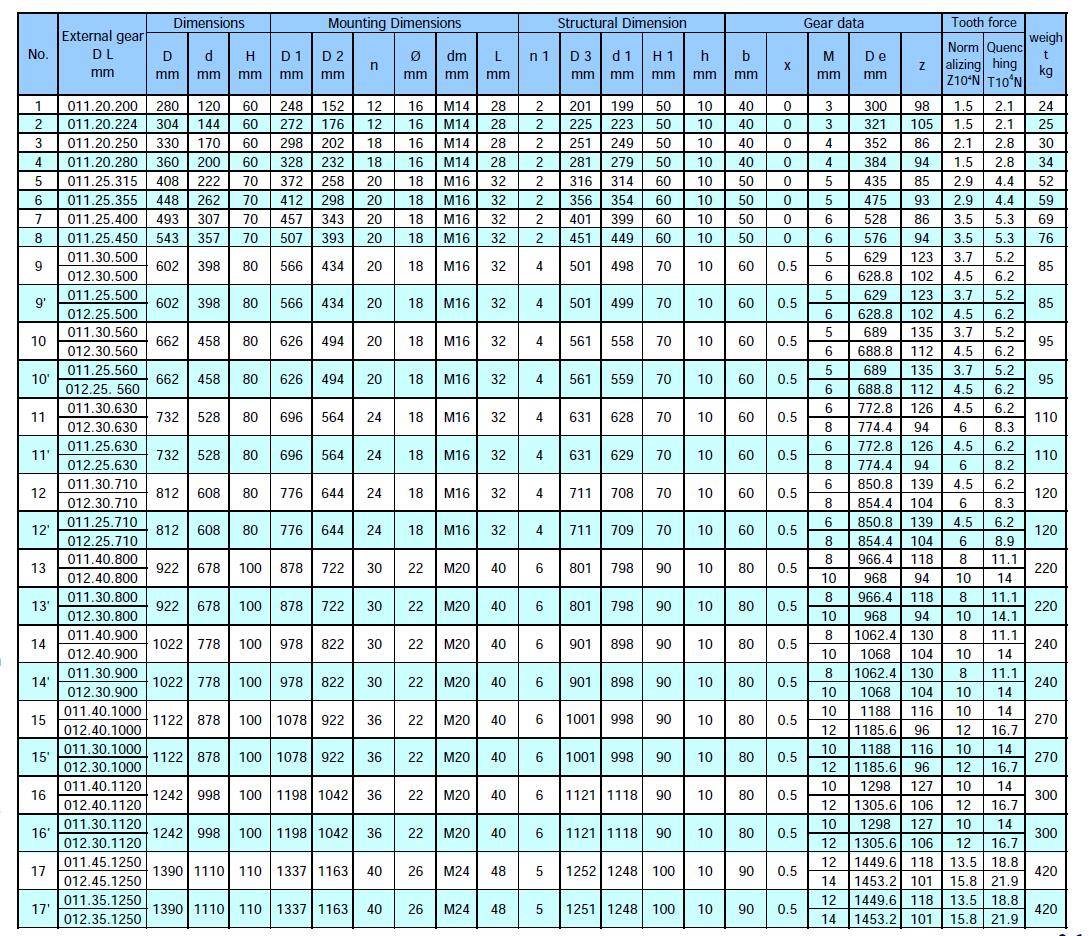

The single row four point contact ball slewing ring bearing is mainly used for window clearner, you can see following specification.

Xuzhou Wanda Slewing Bearing Co.,Ltd is professional in produce slewing bearing for window cleaner. If you have any question, just feel free to contact us

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.