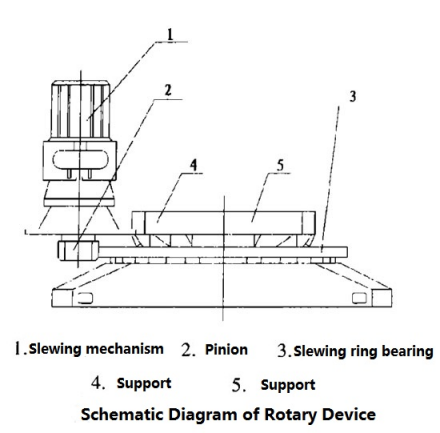

The slewing mechanism is composed of a supporting device, a slewing bearing and a turntable. The slewing bearing is an important force-bearing component. It not only bears the dead weight of the rotating part of the crane, but also bears the vertical force of the lifting load and the force of the tipping moment. During use, there must be wear and tear, and the performance of related mechanical parts will gradually deteriorate or even be damaged.

Common faults of the slewing mechanism mainly include excessive slewing bearing clearance (wild movement), slow movement (weakness) or immobility of the slewing system, abnormal system pressure, and oil leakage. How can I solve a problem?

1. The slewing bearing clearance is too large (open movement)

This is because the worm gear, driving gear and slewing ring gear of the slewing reducer are seriously worn. Please check the clearance with a dial indicator. If it is too large, the slewing ring bearing should be disassembled and replaced and related parts replaced.

2. The slewing system moves slowly (weak) or does not move

The hydraulic motor is malfunctioning, the reducer is malfunctioning, there is an overload, the overflow valve, the manual control valve is malfunctioning. Damage to the gear of the slewing reducer, the plunger or bearing of the hydraulic motor is stuck or severely worn, and the output shaft of the hydraulic motor is broken. These problems will cause the slewing system to move slowly or not move. Check and adjust the faulty parts and replace them if necessary. If it is overloaded, check the lifting weight again.

3. System pressure is abnormal

If the crane is under no load or light load, the sound and speed during its rotation are normal, but when the crane is heavily loaded, it will be difficult to rotate or even unable to rotate. This may be due to the low pressure of the relief valve of the rotary hydraulic system, the wear of the hydraulic motor, the serious internal leakage or the low pressure of the control valve, and the serious wear of the control valve stem, large internal leakage, pressure loss, etc.

The troubleshooting method is first to adjust. One is that under load, it must be adjusted when the rotation is stopped until the rotation is normal under heavy load; the other is to use a pressure gauge to readjust the pressure of the relief valve according to the requirements of the instruction manual (the pressure of the rotation pressure) The size is related to the model); secondly, the hydraulic motor and the control valve are overhauled, and the worn parts are replaced.

4. Oil spill

If the joint surface of the hydraulic component leaks, it should be removed for cleaning, and the joint surface should be grinded with oilstone or fine sandpaper. If possible, it can be processed with a grinder; if the threaded connection of the pipeline is loose, tighten it; seals Replace the damaged ones; if the casing of the hydraulic component leaks, the casing or component must be replaced.

Xuzhou wanda slewing bearing is professional in slewing bearing and slewing drive. If you have any demand, please contact us freely. We must give you the most competitive price!

Post time: Jun-19-2021