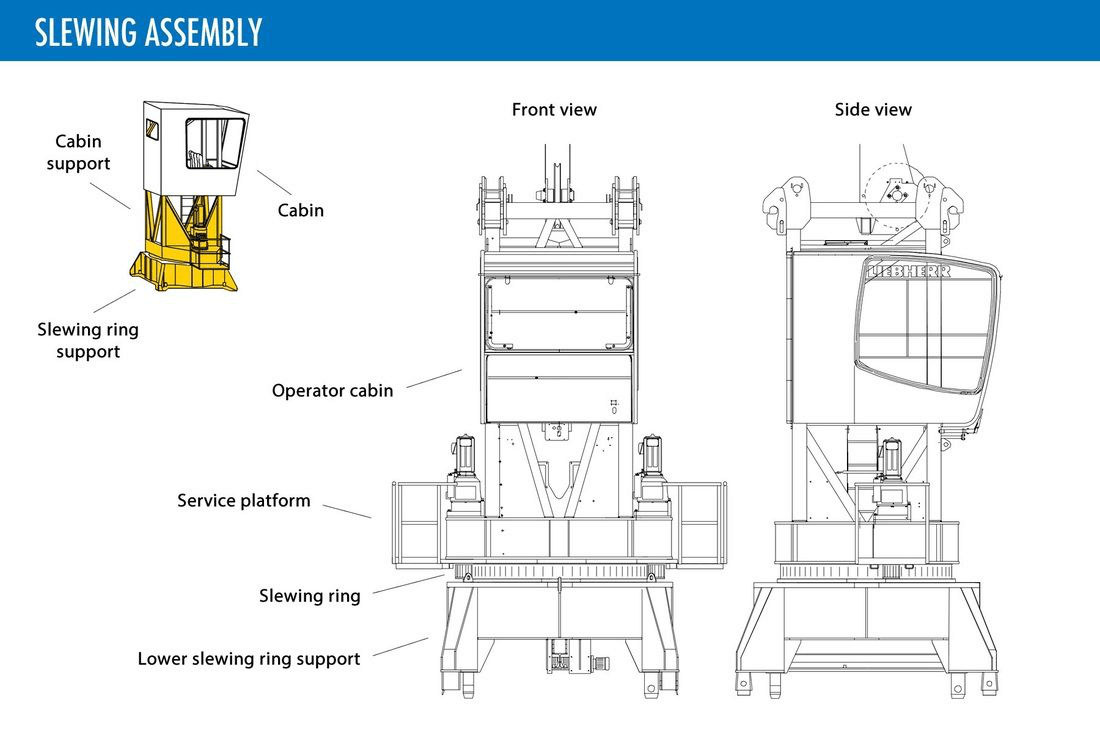

The slewing bearing mechanism of the tower crane is mainly composed of slewing bearing, slewing drive and upper and lower support. The tower crane slewing bearing assembly in the working process will often be not smooth operation and noise exceeds the standard (abnormal noise) fault. The author combined with his own working experience from the slewing bearing, slewing mechanism and slewing bearing faults respectively, in the manufacturing process, assembly testing, equipment maintenance and other aspects of their own opinions and suggestions.

Tower crane slewing ring failure prevention measures and maintenance

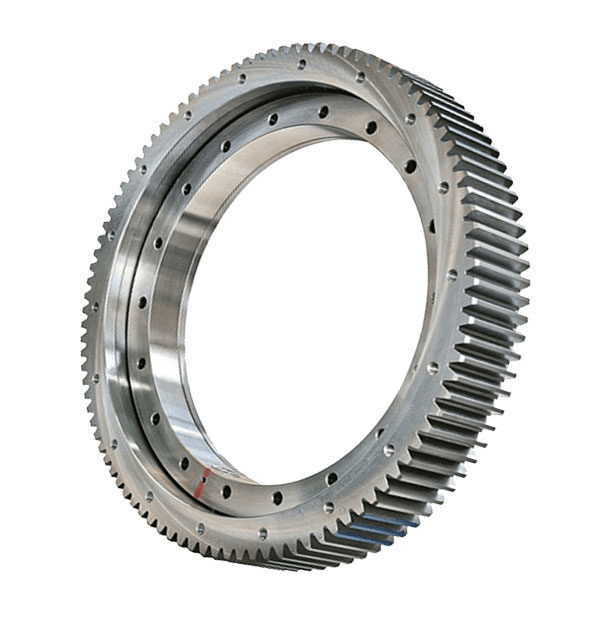

1.slewing ring gear requirements

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the slewing bearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of the slewing bearing.

2. Slewing bearing internal lubrication

In daily use should be timely, on time, according to the instruction manual for each component according to the lubricant, lubrication, lubrication cycle provisions for lubrication. Corresponding ball slewing ring is generally refilled every 100 hours of operation, roller slewing ring is refilled every 50 hours, for dusty, high humidity, high temperature difference of the special working environment should shorten the lubrication cycle. Each lubrication must fill the raceway until the lubricant seeps out, filling while slowly rotating the slewing bearing to make the grease evenly filled. By filling the lubricating oil maintenance, it can reduce the friction between the gear pair, slow down the wear rate of the gear ring, the formation of the oil film can also play the role of shock absorption ring, eliminating part of the vibration energy generated in operation. In addition, the lubricating oil film can also be a good lubricating clean the friction surface, prevent corrosion, and eliminate the influence of iron particles on the friction surface. So as to reduce the frictional noise in operation and increase the service life of the slewing bearing.

3.Fastening bolts

The connection bolts of the slewing bearing and the upper and lower slewing bearing are subjected to axial pulsating load in addition to the preload, which will cause the bolts to be stretched or the joint surface to be deformed, causing the bolts to loosen. Bolt joint loosening preload does not reach the required axial clearance increases, rolling body by a large overturning torque rotation, raceway edge by huge contact stress, resulting in raceway edge damage. A city had a Q T Z 25 tower crane upper structure overturning accident, the direct cause is the slewing bearing and the upper slewing bearing bolts in the non-specified conditions of work, resulting in each bolt group in turn, successively subjected to more than its carrying capacity of the bolt group. This resulted in the upper structure of the tower (with its slewing bearing) breaking away from the tower structure and toppling over.The slewing bearing bolt tightening and its strength level selection is very important. Therefore, the slewing bearing bolt fastening and its strength level selection is very important.

4. Installation and Operation

Installation of slewing ring should be selected with high strength bolts, bolts and nuts should comply with GB3098.1 and GB3098.2 standard requirements prohibit the use of spring washers. Before tightening the mounting bolts, the sizing gear meshing adjustment (side clearance) should be carried out to ensure that the slewing bearing and pinion mesh to meet the requirements. Tighten the mounting bolts should be at 180°, the installation plane must be clean and flat, no burrs, iron shavings and other debris, the plane must meet the requirements.

Tower crane slewing ring in operation will often also have broken teeth failure, so the tower crane in operation should also take into account the wind impact on the slewing ring, if more than the specified wind operation or stop operation after the crane boom can not rotate freely with the wind, this may damage the gear and the slewing bearing engagement or slewing ring, serious accident will occur. So the tower crane in the installation and operation should do a detailed inspection.

Post time: Dec-22-2020