With the vigorous development of the industrial products, such as Automation equipment, industrial robots, filling machines etc. ,many machines need slewing bearing, So the demand for slewing bearings has also risen sharply, but many users do not know how to install slewing bearings correctly. In response to this problem, the XZWD slewing bearing manufacturer with 20 years of slewing bearing production experience gives the following installation methods.

Slewing bearing installation instructions

(1) The bolt holes on the installation plane must be aligned with the installation holes on the slewing bearing

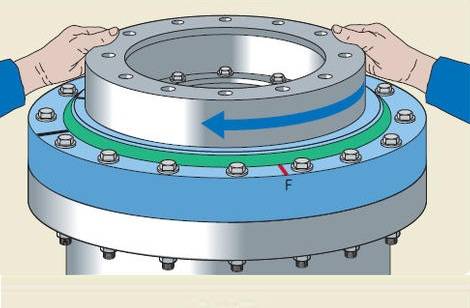

(2) The hardened soft belt of the slewing ring raceway (external mark “S” or blocked hole) should be placed in the non-load area and the non-constant load area. The soft belts of the inner and outer raceway should be installed staggered 180°. On lifting and excavating machinery, the soft belt of the slewing ring should be placed at an angle of 90°with the direction of the boom (that is, the direction of the maximum load).

(3) Hang the slewing ring on the support seat, and check the contact between the slewing ring plane and the support with a feeler gauge. If there is a gap, a gasket can be used to level up to prevent the bolts from deforming after tightening, and affecting the performance of the slewing ring.

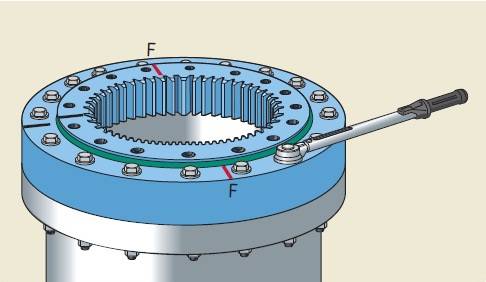

(4) Before tightening the mounting bolts, adjust the backlash according to the highest point of the radial runout of the gear pitch circle (three teeth marked with green paint). After the bolts are tightened, perform a side clearance check on all the gear rings.

(5) High-strength bolts should be used for slewing bearing installation bolts, and bolts of appropriate strength grade should be selected according to the force. The tightening of the bolts should be carried out symmetrically and continuously in the 180° direction, and finally tightened in sequence to ensure that the bolts on the circumference have the same pre-tightening force. The installation bolt washers should be quenched and tempered flat washers, spring washers are prohibited.

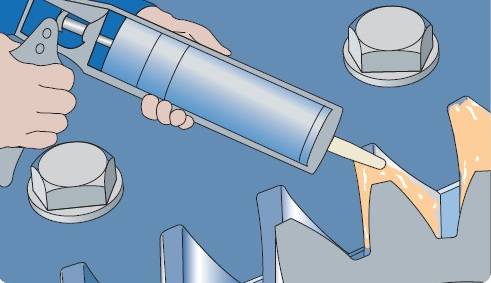

(6) After the installation work is finished, the dirt and dust on the slewing ring should be removed, and the exposed part should be painted with anti-rust paint, and the raceway and gear parts should be painted with grease.

If you have any more question on the slewing ring bearing, just feel free to contact us. Please trust XZWD slewing bearing is not only sell slewing bearing, but also could supply the solution for you!

Post time: Aug-07-2020