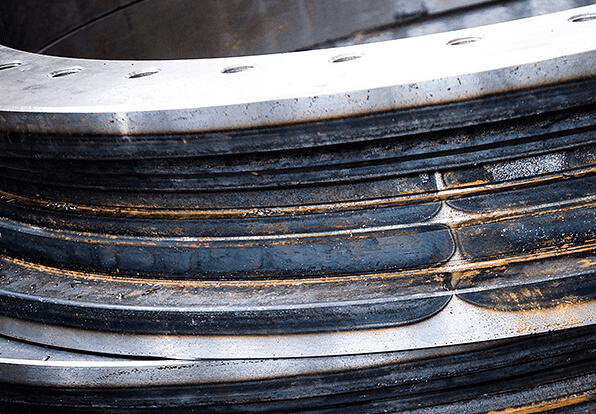

There are two types of slewing ring damage, one is the raceway damage, and the other is the broken tooth. The raceway damage accounts for more than 98%, so the quality of the raceway is a key factor affecting the life of the slewing ring. Among them, raceway hardness, hardened layer depth, raceway curvature radius and contact angle are the four most important factors that affect raceway quality.

1. Raceway hardness

The quenching hardness of the slewing ring raceway has a greater impact on its rated static load. If the rated static load is 1 at 55HRC, the corresponding relationship between the rated static load of the bearing and the hardness of the raceway is as follows:

|

Raceway hardness HRC |

60 |

59 |

58 |

57 |

56 |

55 |

53 |

50 |

|

Rated static load |

1.53 |

1.39 |

1.29 |

1.16 |

1.05 |

1 |

0.82 |

0.58 |

The slewing bearing from XZWD slewing bearing company raceway hardness is 55HRC~62HRC.

2.Depth of hardened layer of raceway

The necessary depth of hardened layer is the guarantee that the slewing ring raceway does not spall. When the slewing bearing bears the external load, the steel ball and the raceway change from point contact to surface contact, and the contact surface is an elliptical surface. In addition to the compressive stress, the raceway is also subject to shear stress, and the maximum shear stress occurs at a depth of 0.47a (the major semi-axis of the contact ellipse) below the surface, This is also the reason why the hardened layer depth is specified in the standard according to the diameter of the steel ball instead of the diameter of the slewing ring, and the minimum guaranteed value is given in the standard. The rated static load C of the bearing is proportional to the depth of the hardened layer H0.908. If the hardened layer depth required to be 4mm is only quenched to 2.5mm, the bearing static load C will be reduced from 1 to 0.65, the probability of damage to the slewing bearing due to fatigue peeling will be greatly increased.

For example, the slewing bearing raceway layer depth013.35.1250 raceway is ≥ 3.5mm.

3.Curvature radius of the raceway

The raceway curvature radius refers to the curvature radius of the raceway in the vertical section. The ratio t of the radius of the raceway to the radius of the steel ball also significantly affects the rated static load and fatigue life of the slewing ring. When t=1.04, the rated static load and the fatigue life is 1, and the corresponding relationship between the rated static load and fatigue life of the slewing ring and t is as follows.

| Curvature ratio | 1.04 | 1.06 | 1.08 | 1.10 |

| Rated static load | 1 | 0.82 | 0.72 | 0.65 |

| Fatigue life | 1 | 0.59 | 0.43 | 0.33 |

It can be seen from the above table that the larger the radius ratio, the lower the rated static load and the shorter the service life.

4.Raceway contact angle

The contact angle refers to the angle between the line connecting the contact point of the steel ball on the raceway and the center of the steel ball and the radial section (horizontal plane) of the slewing bearing. The rated static load C of the slewing ring is linearly proportional to SINα, and the original contact angle is generally 45°. When the slewing bearing has a gap, the actual contact angle is greater than the original contact angle. The larger the gap, the larger the actual contact angle. Within the gap range specified by the standard, it will generally increase by 2°~10°, that is, the actual contact angle will reach 47°~55°, which is a favorable change for the bearing capacity. But if the original contact angle and gap are large, the actual contact angle will exceed 60°. As the raceway wears, the gap will further increase and the actual contact angle will also increase. At this time, the contact ellipse may exceed the edge of the raceway. , The actual force of the raceway will be higher than the theoretical calculated stress, which will cause the edge of the raceway to collapse and the slewing bearing will fail.

For example, the original contact angle of the slewing bearing 013.40.1250 is 45°.

Thanks for reviewing this article, if you have any question on slewing ring bearing, just feel free to contact us!

Post time: Aug-20-2020