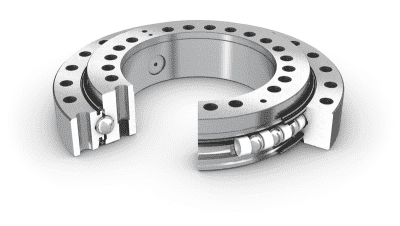

In the CNC vertical lathe equipment, the slewing bearing is one of the core components that reflect the machine overall performance and realize the machining accuracy of the workpiece. We require it to run at high speed and withstand heavy workpieces at the same time, with precise running accuracy and very high anti-tilting torque capacity, and the slewing bearing is the key to complete the support table.The installation and preload adjustment of the turntable slewing bearing is also difficult, the alignment is more difficult to ensure, the overall precision of the table is difficult to improve.

As a result, more compact crossed roller slewing bearings are used that offer material cost savings, simplified design solutions, higher limiting speeds, improved running accuracy and stability, and higher load carrying capacity and rigidity. This article describes application for slewing bearing in CNC vertical lathe to achieve their perfect engineering properties.

1.Run-out accuracy

Slewing bearing run-out can be divided into synchronous run-out and asynchronous run-out, in which the influence of synchronous run-out on the overall run-out of the table can be minimized by grinding the table surface.Therefore, the better control of the slewing bearing asynchronous run-out, the smaller the final radial and axial run-out of the worktable and the higher the running accuracy. In the choice of slewing bearing brand and precision level, it is recommended not only focus on slewing bearing assembly run-out, but should have an in-depth understanding of the impact of slewing bearing asynchronous run-out precision standards.

2.Shape and location tolerance

The slewing bearing shaft mounting surfaces and gear ring require flatness, perpendicularity, roundness and cylindricity that are consistent with precision slewing bearings. Controlling these form and position tolerances not only provides better assembly accuracy, but also avoids stress concentrations caused by excessive eccentricity of the slewing ring inner and outer ring and prolongs the service life of the slewing bearing. Regarding the processing standards of form and slewing ring position tolerances, it is recommended to consult us directly to match their slewing bearing accuracy.

3. Axial preload

The cutting test of CNC vertical lathes pays much attention to the roughness of the workpiece’s end face and outer circle, and one of the keys to determine its performance is the rigidity of the system. The rigidity of the system includes the rigidity of the frame structure, the rigidity of the slewing bearing, etc. The rigidity of the slewing bearing often depends on slewing bearing axial preload.

Therefore, it is very important to consider the influence of temperature and load, and set the axial preload of the slewing bearing.

Post time: Aug-31-2020