Factory source Double Row Ball Slewing Bearing - XZWD high precision single row ball slewing ring bearing without gear – Wanda

Factory source Double Row Ball Slewing Bearing - XZWD high precision single row ball slewing ring bearing without gear – Wanda Detail:

1.Point-contact rolling mode slewing bearing

The point contact rolling mode of operation is mainly used for four point contact ball slewing ringand crossed roller slewing ring.The working principle of the point contact radial and axial force combination to withstand the high quality requirements of the steel ball, and the track should be uniform angle.

2. Face-to-face rolling mode slewing bearing

Face contact rolling combined mode of work is mainly used for three rows of roller slewing bearing, it has the advantage of large contact surface, uniform bearing capacity and flexible rolling.

3. Face contact roller-slide combined mode slewing bearing

The face contact roller-slide combined working method is mainly used for rotary turntable bearings, and now the new rotary bearings are compact and highly accurate, so it is most suitable to use the face contact roller-slide combined working method.

| Type |

|

| Outside Diameter | 300 – 4845 mm |

| Bore Size | 120 – 4272 mm |

| Gear Options | External gearInternal gear

Without gear |

| Brand Name | WANDA |

| Raw material | 50Mn, 42CrMo |

| Rolling element | Ball or roller |

| Place of Origin | Jiangsu, China (Mainland) |

| Certificate | ISO9001:2008, SGS |

| Warranty | 1 year |

| Delivery Time: | 30-45DAYS |

| Payment Terms: | L/C,T/T |

| OEM/ODM | Available |

| Packaging Details: | 1:Filling with rust-proof oil 2:packing with protective layers 3:Fixed in wooden box |

4. Roll-slide combination of rolling mode slewing bearing

Rolling and sliding combination of rolling work mode is mainly used for ball column joint slewing bearing, this slewing bearing of small eccentric long life, has the advantages of roller and ball dual structure.

Product detail pictures:

Related Product Guide:

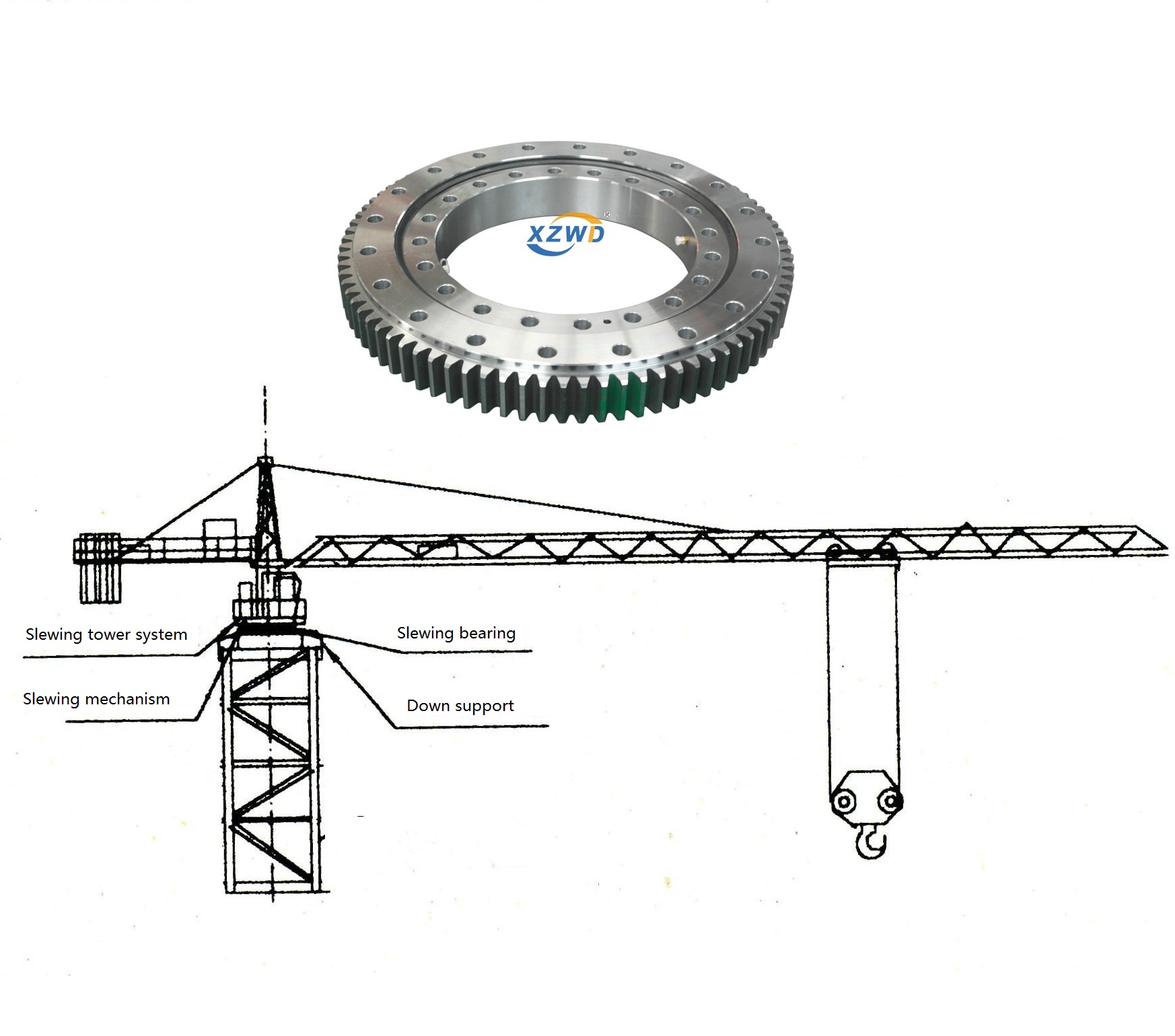

Car parking system used slewing bearing

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for Factory source Double Row Ball Slewing Bearing - XZWD high precision single row ball slewing ring bearing without gear – Wanda , The product will supply to all over the world, such as: Georgia, Montreal, Macedonia, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!