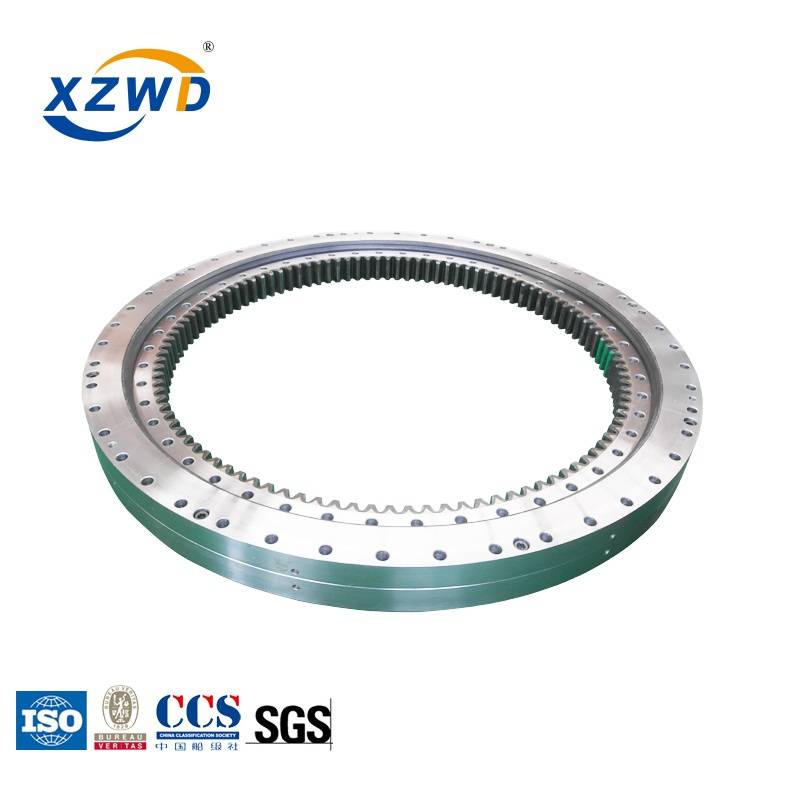

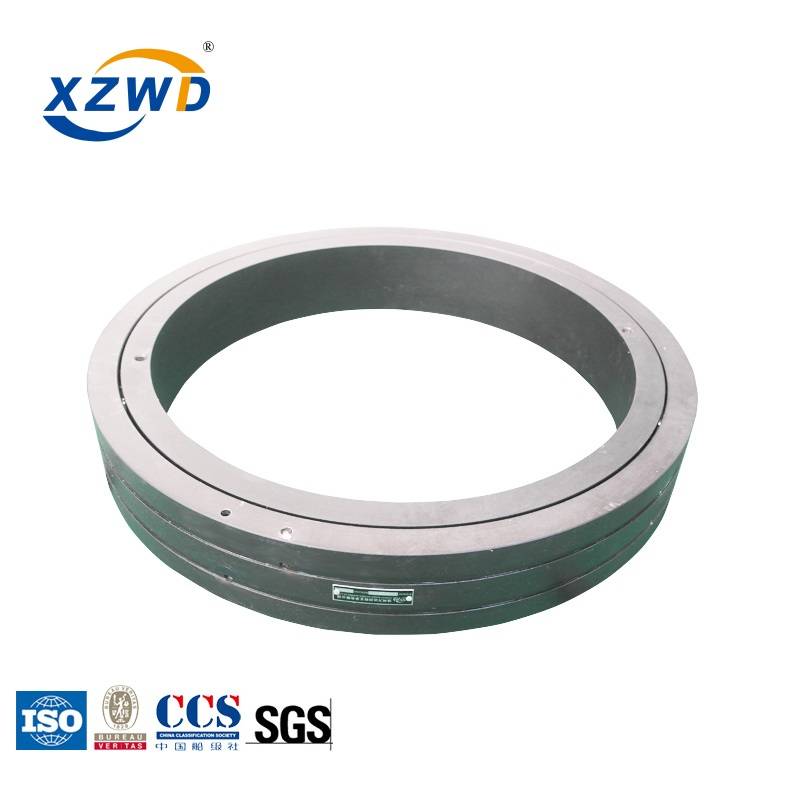

Discountable price Ball Bearing Turntable - High quality 4 point contact ball turntable bearing for wind turbines – Wanda

Discountable price Ball Bearing Turntable - High quality 4 point contact ball turntable bearing for wind turbines – Wanda Detail:

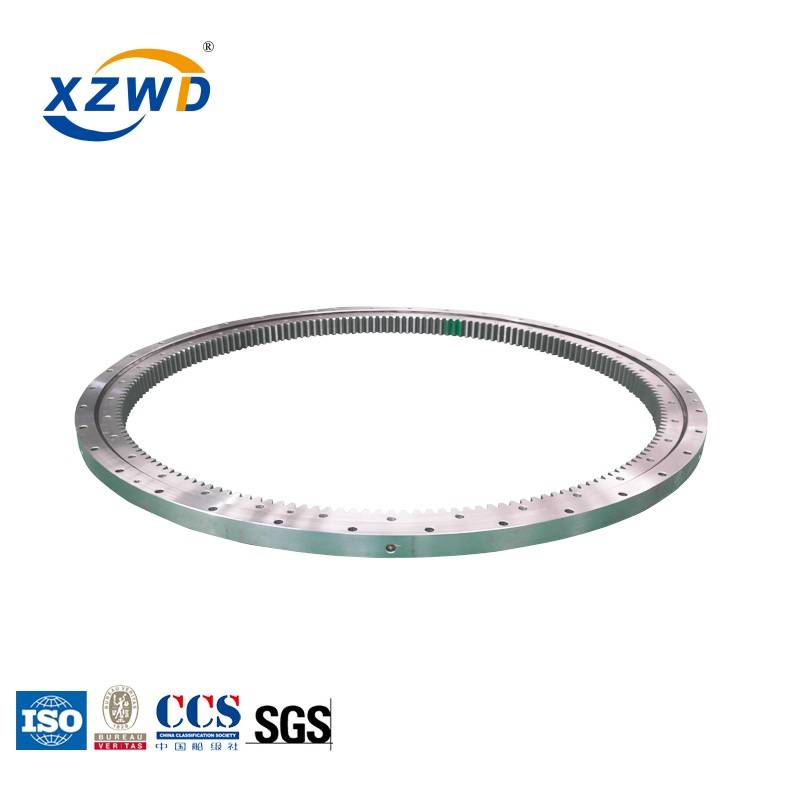

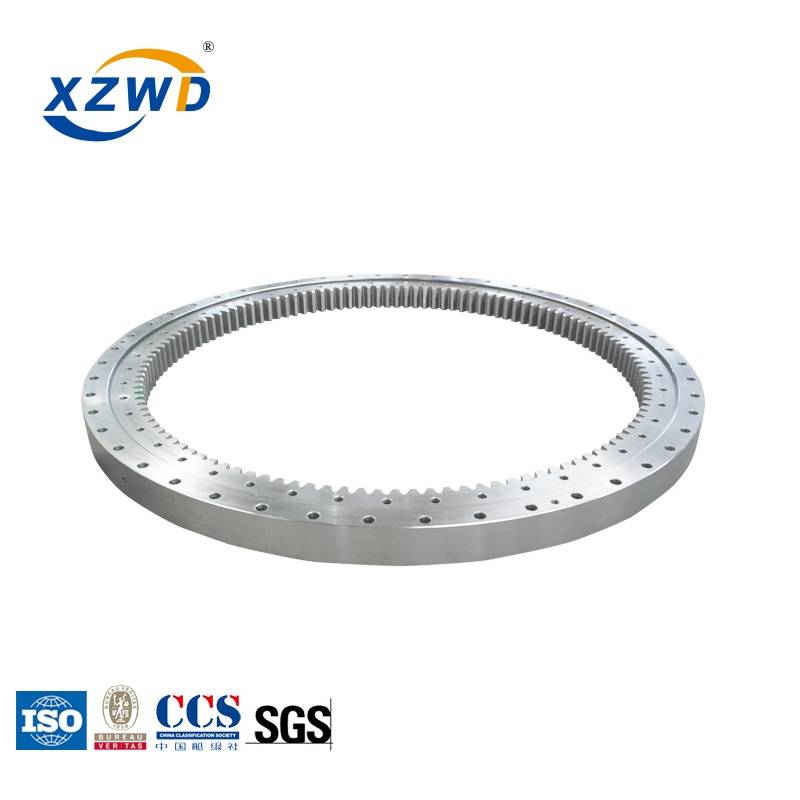

The raceway finish by grinding, the high level machining process and grinding process that ensured the precision for the double row slewing rings.

Mining equipment are characterized by their tough working conditions, like high temperature and heavy dust, and they are usually heavy-duty machines requiring slewing ring bearings of high load capacity.

The clearance cage enables the friction between rollers to be disappeared and prevent rollers from falling down on one side, which is able to obtain a stable torque. The rollers are orthogonal arranged, so only one set of the Crossed Roller Bearings can withstand the loads from different directions. Compared with the traditional series bearing, the current series bearings have increased the level of rigidity by three to four times.

XZWD Three-row roller slewing ring gear or Double axial Combination of Rollers and Ball swing bearing is apply for very high axial loads & moments as well as small radials efforts aggressive conditions.

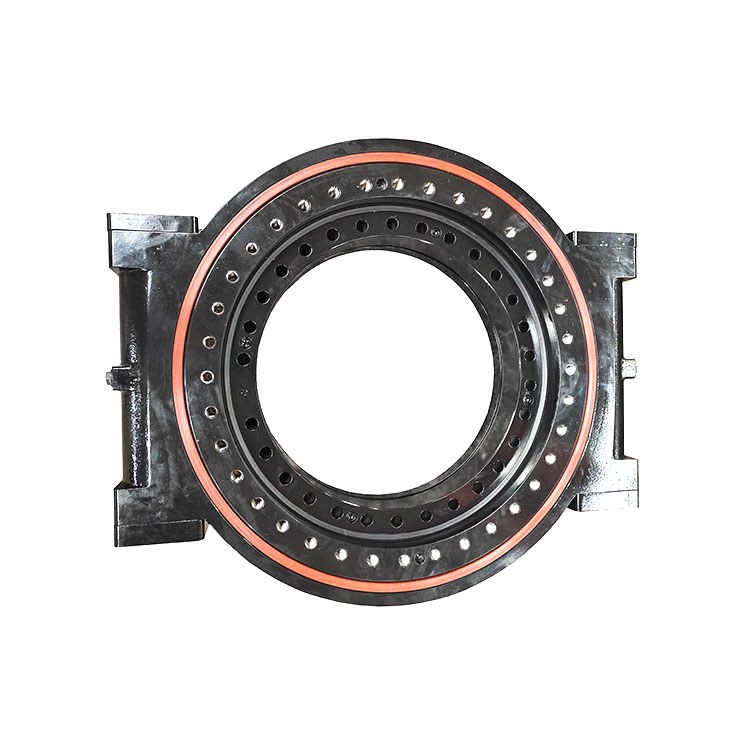

We uses special sealing system gives fully tight bearings and we also propose integrated bearings with a lubrication system for such tough environment.

The three row roller slewing ring bearing and combined roll/ball swing bearings for stacker reclaimers, bucket wheels, ship loaders and Unloaders are very demanding applications.

Slewing Ring Gear and Swing Bearings are used in various kinds of port crane equipment, among gantry cranes, harbour and shipyard cranes. All those are of particular interest for our products.

without the mounting holes on both inner ring and outer ring, its requires a presser flange and housing for the installation. In addition, because it has an integrated inner/outer ring structure and is equipped with washers, the installation has little impact on its performance, which can achieve the stable rotation accuracy and torque.

The cranes require slewing ring bearings with high load carrying capacity, higher reliability and safety. Our three-row roller with large diameter slewing bearings are well performed with all major classification requirements like DNV, ABS, LR,BV, GL, NK approvals.

We have strict production schedule to assure the delivery time, the production schedule as below:

A. Forging purchase period: 15-20 days

B. Production process:

1. Rough turning: 2-3 days

2. Raceway heat treatment: 2 days

3. Fine turning: 2 days

4. Gear cutting: 4-5 days

5. Drilling: 2-3 days

6. Final turning: 2 days

7. Assembling and Inspection: 2 days

C. Packing and delivery to Port: 3-5 days

Totally about 40-50days

We also supply Ball and Cross Rollers technology, and propose BALL AND ROLLER COMBINATION STRUCTURE design for very high radial loads and high speed like for active heave compensation winches. We also offer unique sealing complying with seawater environment, as well as thin stainless steel layer to increase lifetime on seal contact surface.

For large Offshore cranes, Bulk Handling, Marine cranes our Heavy design is also a popular solution, meeting requirements for huge axial loads& tilting moments.

Product detail pictures:

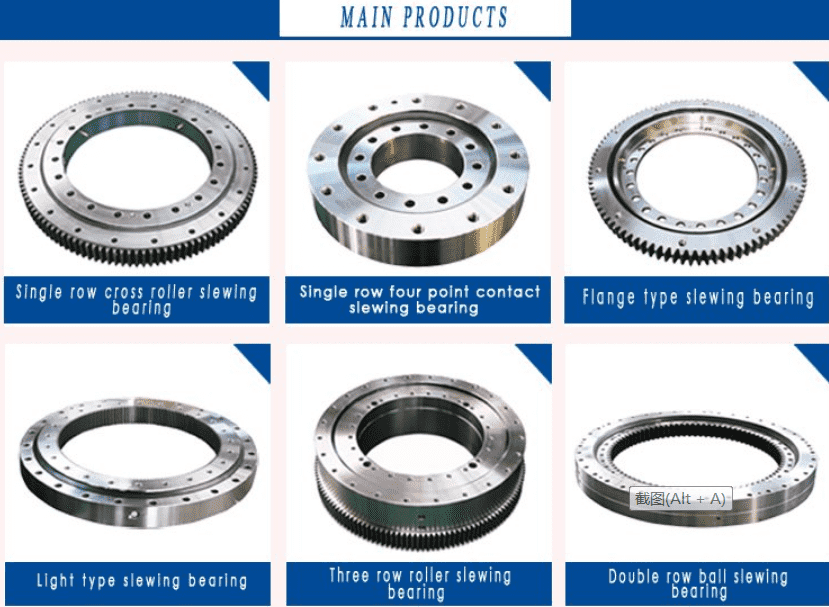

Related Product Guide:

Car parking system used slewing bearing

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Discountable price Ball Bearing Turntable - High quality 4 point contact ball turntable bearing for wind turbines – Wanda , The product will supply to all over the world, such as: Senegal, Philadelphia, Irish, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.