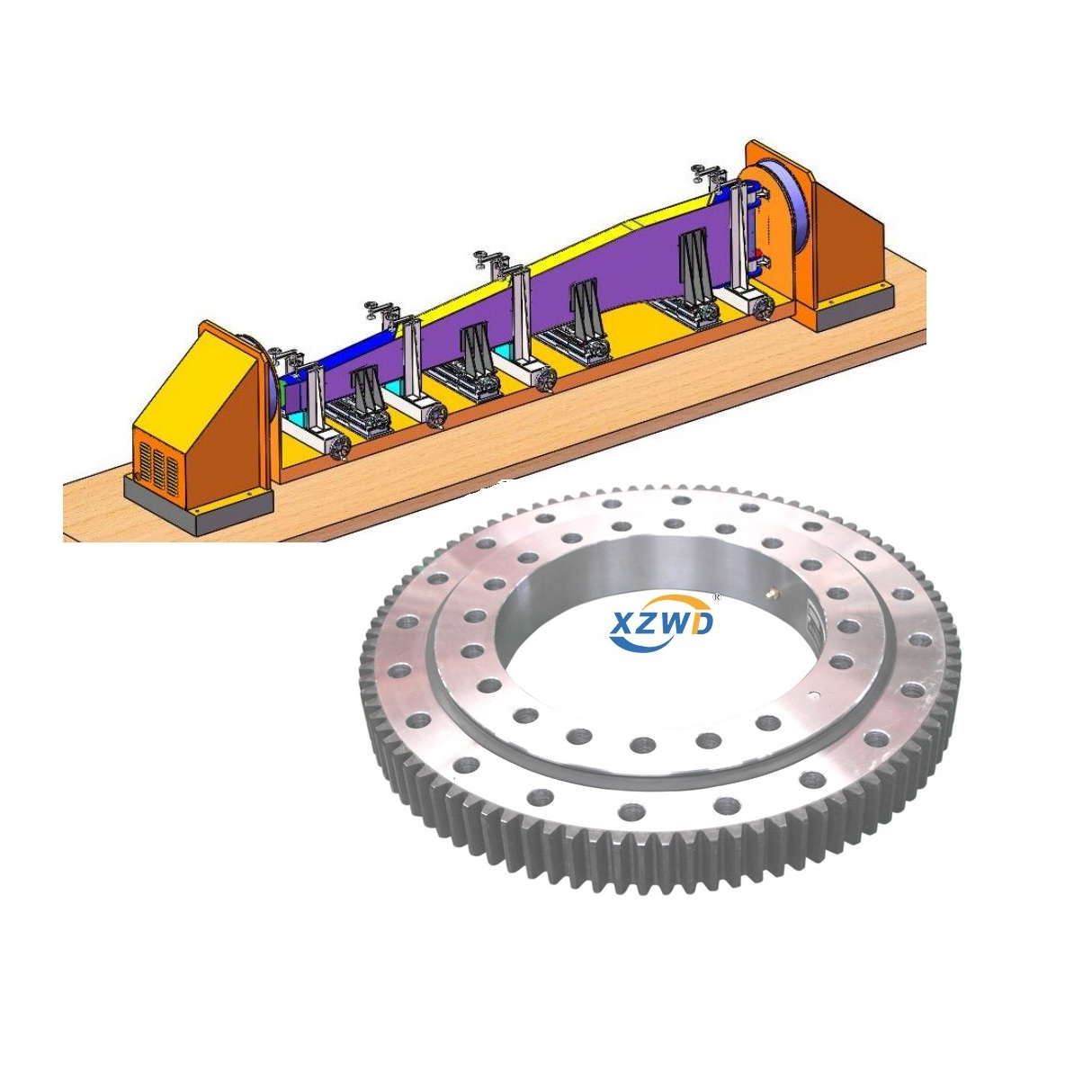

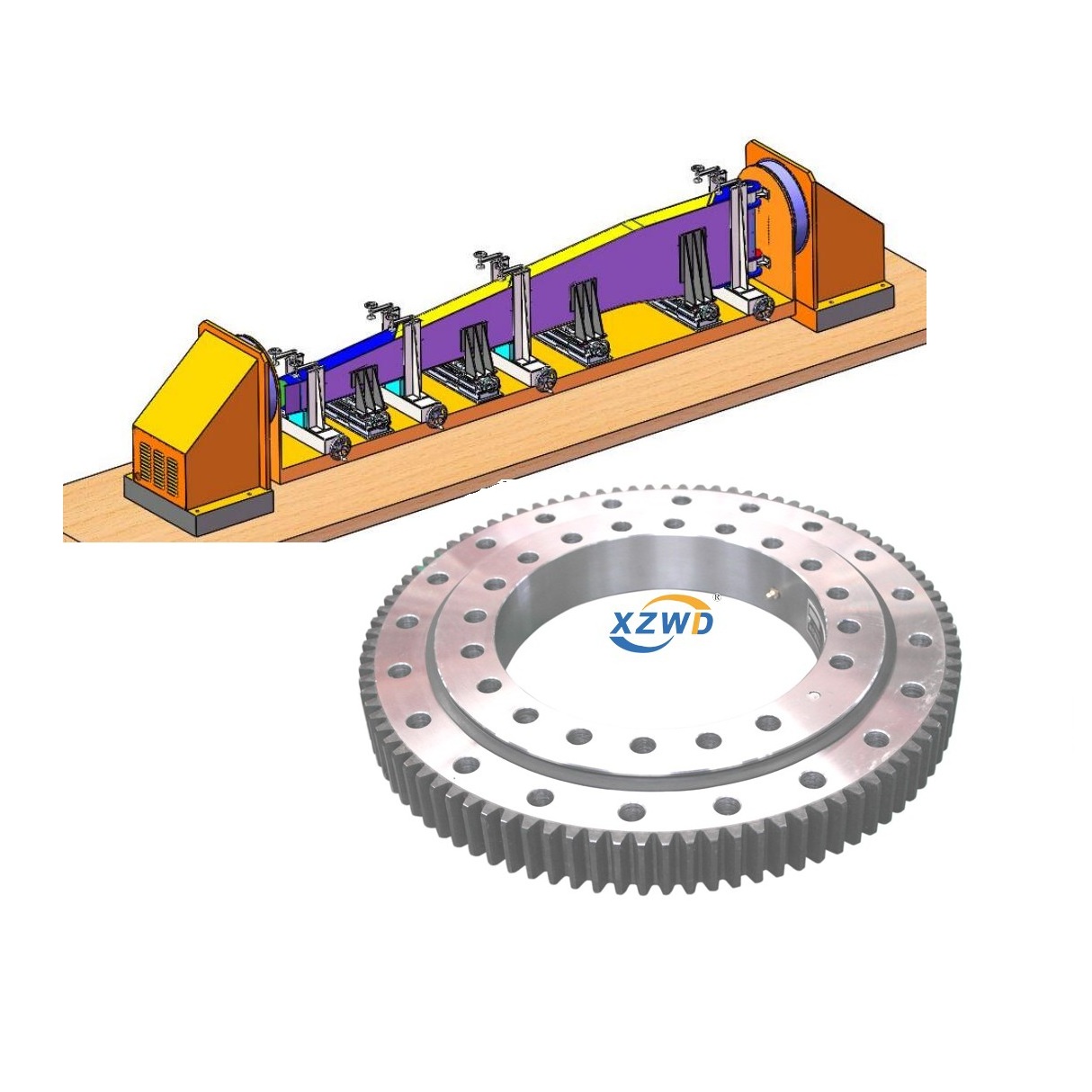

China factory supply Slewing bearing for the welding positioner

The positioner is mainly composed of a worktable, a slewing mechanism, a turning mechanism, a conductive device, a frame and an electric control box. The positioner is a special welding auxiliary equipment, which is suitable for the welding position of the slewing work to obtain the ideal processing position and the welding speed, can be used in conjunction with the operating machine and the welding machine to form an automatic welding center, and it can also be used for the displacement of the workpiece during manual operation.

The worktable rotation adopts frequency converter stepless speed regulation with high speed regulation accuracy. The remote control box can realize remote operation of the worktable, and can also be connected with the operating machine and the welding machine control system to realize linkage operation. The welding positioner is generally composed of a worktable rotating mechanism and a turning mechanism. Through the lifting, turning and rotating of the worktable, the workpiece fixed on the worktable can reach the required welding and assembly angles. The worktable rotation is frequency conversion stepless speed regulation. Satisfactory welding speed can be obtained.

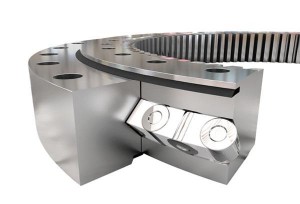

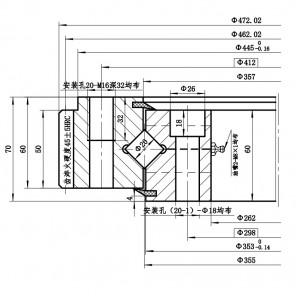

Slewing bearings for positioners generally require high-precision products with small clearances. Our company’s Single row cross roller slewing ring bearing 111 series can meet this application very well. Generally use 111.20.315 or 111.20.355. Please see the below drawing.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.