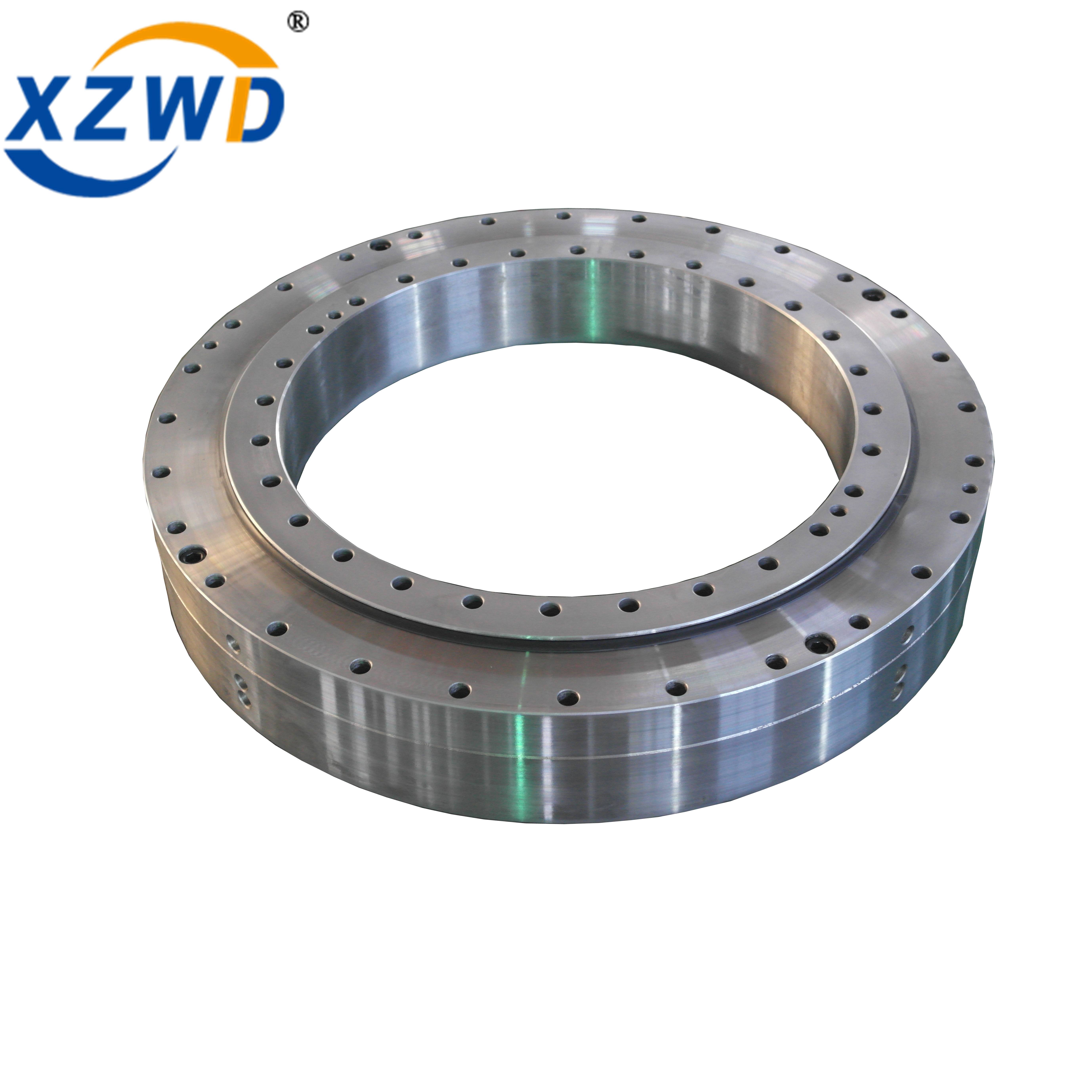

Well-designed Slewing Unit - Non-Geared Three row Roller Slewing Bearing for Heavy Machinery – Wanda

Well-designed Slewing Unit - Non-Geared Three row Roller Slewing Bearing for Heavy Machinery – Wanda Detail:

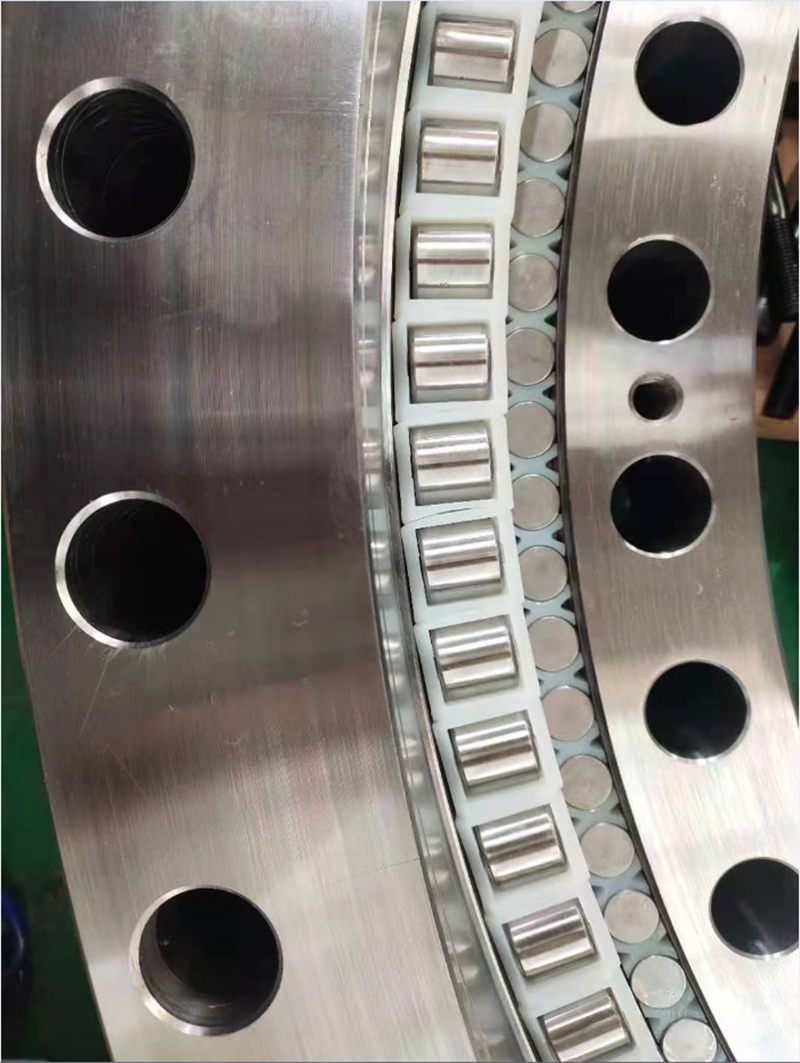

There are three rows of slewing bearings with rollers of different diameters as rolling elements. It is composed of three seat ring, three groups of rollers and spacers,

connecting bolts and dustproof ring. According to differnet load conditions, the upper row of rollers has the largest size, and the lateral rollers have the smallest size.

The upper and lower row of rolling elements bear axial force and verturning moment, while the lateral rolling elements bear radial force. It is a slewing bearing with

the largest bearing capacity. Mostly used in heavy construction machinery.

We also can use the steel cage or copper cage for the slewing bearing, and it used for fast speed.

For slewing bearing, it have three type of teet:

1. Outernal gear slewing bearing

2. Internal gear slewing bearing

3. Non-geared slewing bearing

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Well-designed Slewing Unit - Non-Geared Three row Roller Slewing Bearing for Heavy Machinery – Wanda , The product will supply to all over the world, such as: New Zealand, Rio de Janeiro, Iran, Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!