Single Row Four point Contact Ball Slewing Bearing

-

XZWD high precision four point contact ball slewing bearing for all kinds crane

Our products available including: Single and Double Row Ball, Three Row Roller, Cross Roller Sealed and Unsealed Internal Geared, External Geared and Non-Geared Clearance or Preloaded.

Our Xuzhou Wanda slewing bearing Product type:

1.Single Row Four Point Contact Ball Slewing Bearings.

2.Single Row Crossed Roller Slewing Bearings

3.Double Row Ball Slewing Bearings

4.Three Row Roller Slewing Bearings

5.Thin Section Slewing bearings(Light type).

6.Thin Section Slewing Bearings (Flange type) -

XZWD hot sale best price single row four point slewing ring for rotary equipment

The main raw material of the slewing bearing is ring forgings, and the material is generally divided into 50Mn and 42CrMo. The process is generally divided into normalizing and quenching. In this way, the slewing bearing raw materials can

be divided into 50Mn normalizing material, 50Mn modified material, and 42CrMo positive material. Fire material,42CrMo conditioning material four kinds of combinations. In terms of cost, 50Mn is cheaper than 42CrMo, and the normalizing process is cheaper than the quenching process. -

XZWD High quality Slewing Bearing with internal teeth for Mini Excavator

The light type slewing ring bearing has the same structure with four point contact ball slewing ring bearing,but the weight is light and could be used for some light type machinery applications.

The light slewing bearing ring has been widely used in many applications:

1.Food machinery;

2.Canning machinery;

3.Environmental machinery

-

XZWD single row ball four point contact ball slewing bearing grease

1.Single Row Four Point Contact Ball Slewing Bearings.

2.Single Row Crossed Roller Slewing Bearings

3Double Row Ball Slewing Bearings

4.Three Row Roller Slewing Bearings

5.Thin Section Slewing bearings(Light type).

6.Thin Section Slewing Bearings (Flange type) -

Customized light weight excavator slewing ring bearing

The slewing bearing of a light small excavator is easily damaged. Usually the replacement cycle is 2 to 3 years.

-

XZWD slewing bearings for wind turbine pitch and yaw positions

We,xuzhou wanda slewing bearing has designed and manufactured slewing bearings for wind turbine pitch and yaw positions.

-

China factory High quality Zinc spray surface Wind turbine slewing ring bearing

Wind turbine slewing bearings can also be called wind power bearings. They are a special kind of bearings. They are used in harsh environments, have high maintenance costs and require long life. Slewing bearings for wind turbines mainly include: yaw bearings, pitch bearings, spindle bearings, variable speed bearings, box bearings, generator bearings. The structural forms of slewing bearings for wind turbines mainly include four-point contact ball slewing bearings, crossed roller sl... -

Customized Single row four contact ball Slewing bearing without gear

Customized Slewing bearing

We design the drawing as customer’s requirement

Non-geared Single row four point contact ball Slewing bearing ring

-

XZWD high quality slewing ring bearing for Rota-table trailer

Single row four-point contact ball slewing bearing could be used for flatbed truck trailer.

-

Teeth hardened fast delivery Slewing bearing for Crane

OEM Slewing bearing for customer with bear price

-

XZWD Slewing bearing factory high quality teeth quenched turntable bearing

Raceway heat treatment and tooth heat treatment are the biggest advantages of XZWD slewing bearing co.,ltd.

-

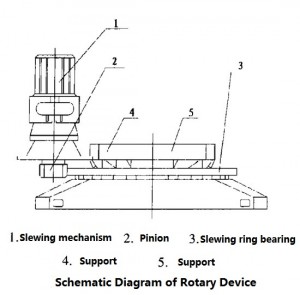

XZWD factory supply slewing mechanism use swing bearing

The slewing mechanism is composed of a supporting device, a slewing bearing and a turntable. The slewing bearing is an important force-bearing component.