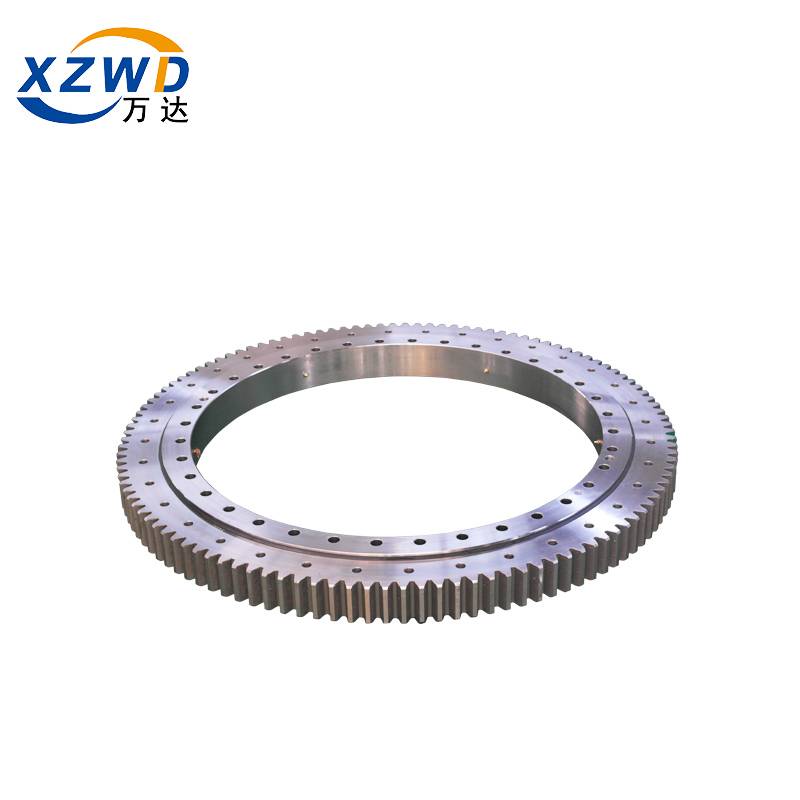

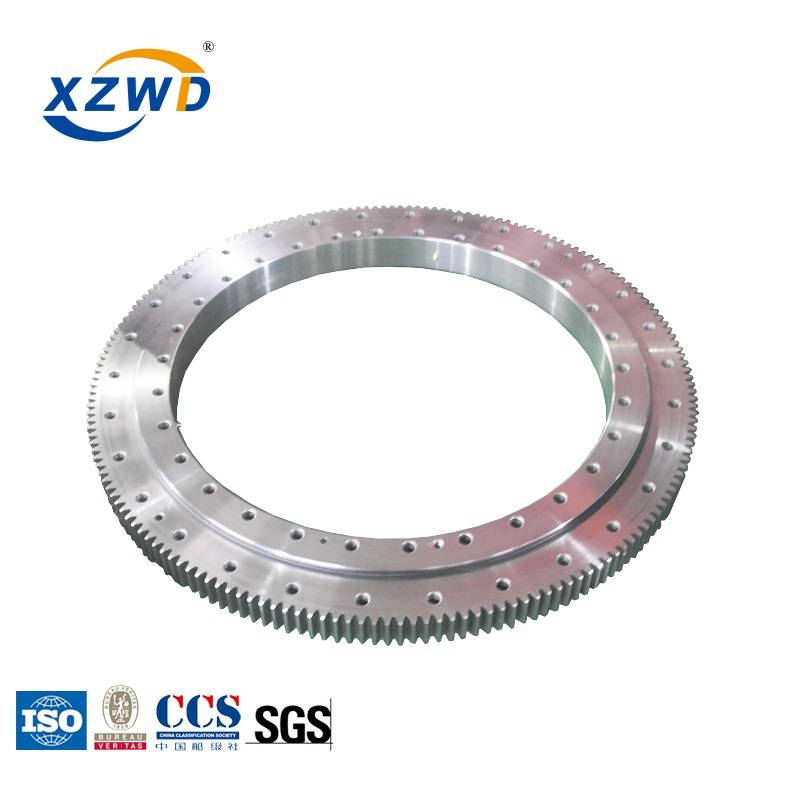

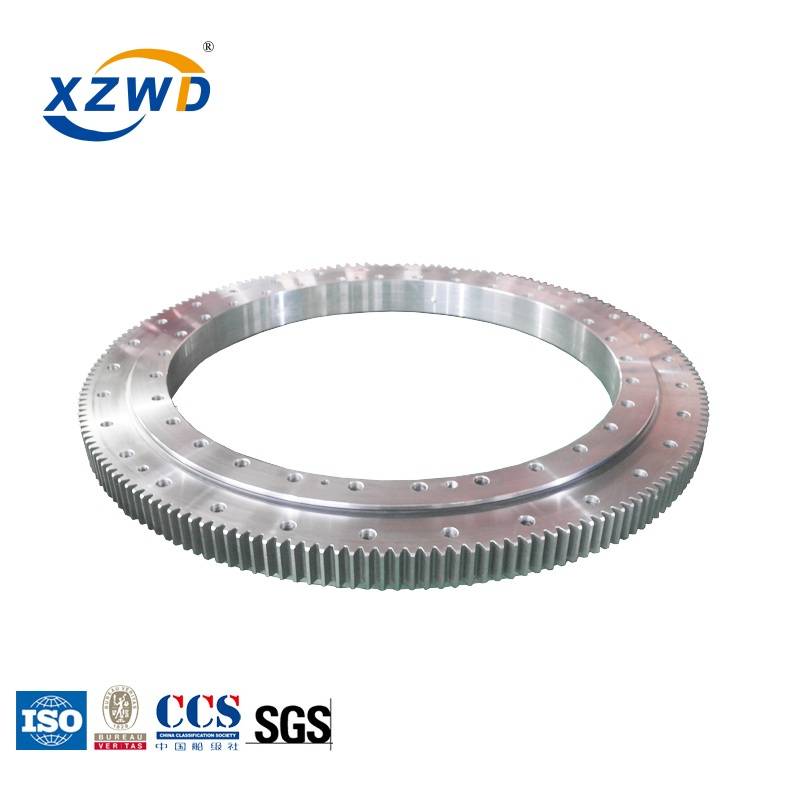

Reliable Supplier Internal Gear Bearing - XZWD Single Row Four Point Ball Slewing Bearing Ring Tunnel Boring Machines – XZWD

Reliable Supplier Internal Gear Bearing - XZWD Single Row Four Point Ball Slewing Bearing Ring Tunnel Boring Machines – XZWD Detail:

Slewing ring can bear axial, radial load and tilting moment load simultaneously. It can be combined with pinion, planetary gearbox and motors…

We have strict production schedule to assure the delivery time, the production schedule as below:

A. Forging purchase period: 15-20 days

B. Production process:

1. Rough turning: 2-3 days

2. Raceway heat treatment: 2 days

3. Fine turning: 2 days

4. Gear cutting: 4-5 days

5. Drilling: 2-3 days

6. Final turning: 2 days

7. Assembling and Inspection: 2 days

C. Packing and delivery to Port: 3-5 days

Totally about 40-50days

The large bearings, tailored individually to match the customer project, can be used for rotating thousands of tonnes of steel, and are characterised by their low torque and high load carrying capacity. In this way, We is able to

support the ongoing development of offshore machine construction, and the ever-larger dimensions at play in this sector.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Reliable Supplier Internal Gear Bearing - XZWD Single Row Four Point Ball Slewing Bearing Ring Tunnel Boring Machines – XZWD , The product will supply to all over the world, such as: Florence, Panama, Ukraine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!