PriceList for Crane Slewing Bearing - large diameter four point contact ball turntable bearing for robot – Wanda

PriceList for Crane Slewing Bearing - large diameter four point contact ball turntable bearing for robot – Wanda Detail:

>> Product type:

1.Single Row Four Point Contact Ball Slewing Bearings.

2.Single Row Crossed Roller Slewing Bearings

3Double Row Ball Slewing Bearings

4.Three Row Roller Slewing Bearings

5.Thin Section Slewing bearings(Light type).

6.Thin Section Slewing Bearings (Flange type)

Applications

wind generator, Marine Crane, Offshore Crane,Harbor mobile crane, Ferris wheel,stacker,Unloader,Construction Machinery,Ladle turret,shield machine,radar and so on

Advantages

1. We can supply various size slewing ring bearings.

2. Type: Non-teeth, internal teeth, external teeth

3. Diameter range: 200mm—–4500mm, Weight range: 20kg——–5100kg

4. Design and manufacture according to customer needs, OEM bearing.

5. High quality bearing, competitive price, prompt delivery and best services.

Standards

| ISO9001 | 2008, SGS, CCS |

| Raw material | 50Mn, 42CrMo |

| Raceway hardening | 55-62HRC |

| Gear hardening | 50-60HRC |

| Lubrication | Grease |

| Warranty | 1 year |

Company Profile

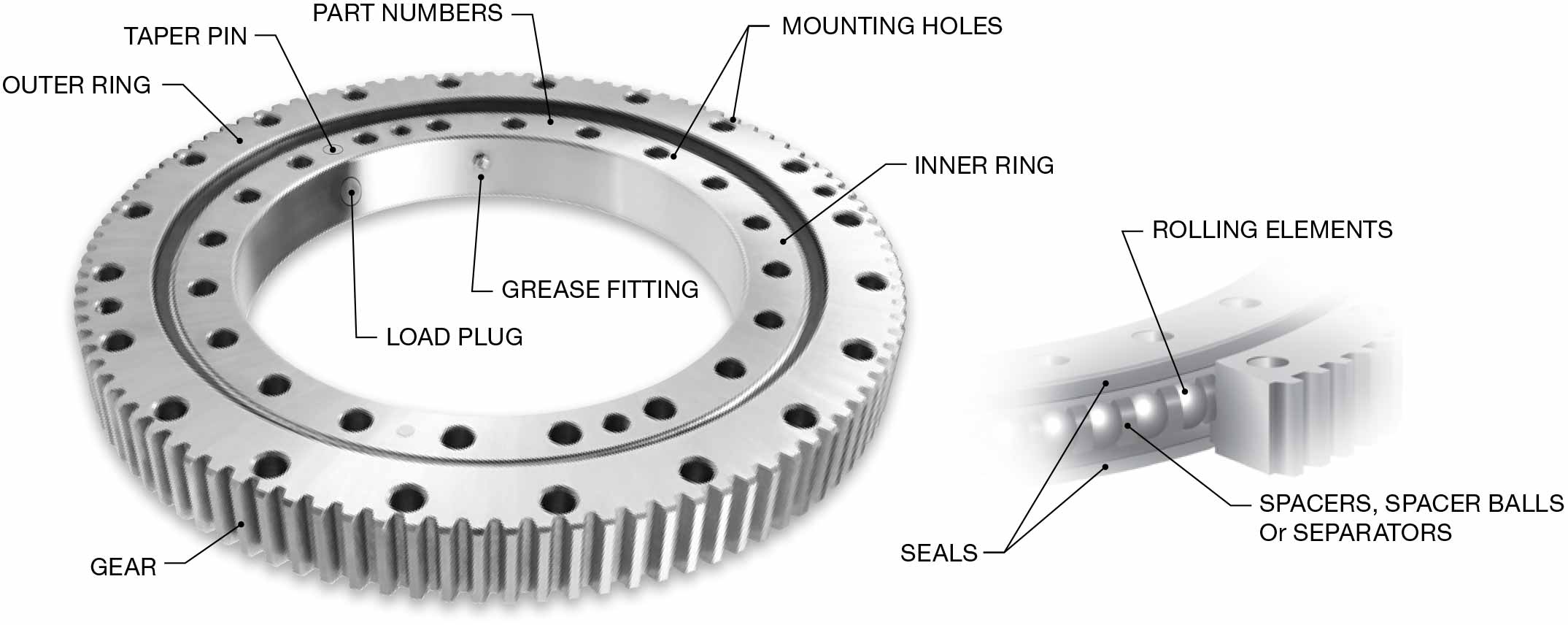

Four point contact bearings

– these slewing rings without preload are robust and proven under very demanding operation; they place only slight demands on the flatness and perpendicularity of the adjacent construction

– they are suitable for applications with low requirements for accuracy and rigidity of the bearing arrangement, for example in simple metalworking machines, wind power equipment and construction machinery

World Famous Global Hot Sale XZWD Four Point Contact Ball Turntable Slewing Ring Bearing

The Single Row Four Point Contact Ball Slewing Bearing is composed of 2 seat rings.It features compact in design,and light in weight.The balls contact with the circular race at four points,via which the axial force,radial force and resultant moment may be born simultaneously.

It may be used for slewing conveyer, welding arms and positioners,light,medium duty cranes,excavators and other engineering machines.

Product available including: Single and Double Row Ball, Three Row Roller, Cross Roller Sealed and Unsealed Internal Geared, External Geared and Non-Geared Clearance or Preloaded

–We respected for our quality and cost effective

–We provide custom bearing designs that meet specific customer requirements

– Timely reply.Quotes are turned around in 24 to 48 hours

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for PriceList for Crane Slewing Bearing - large diameter four point contact ball turntable bearing for robot – Wanda , The product will supply to all over the world, such as: Lahore, Hongkong, Jordan, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.