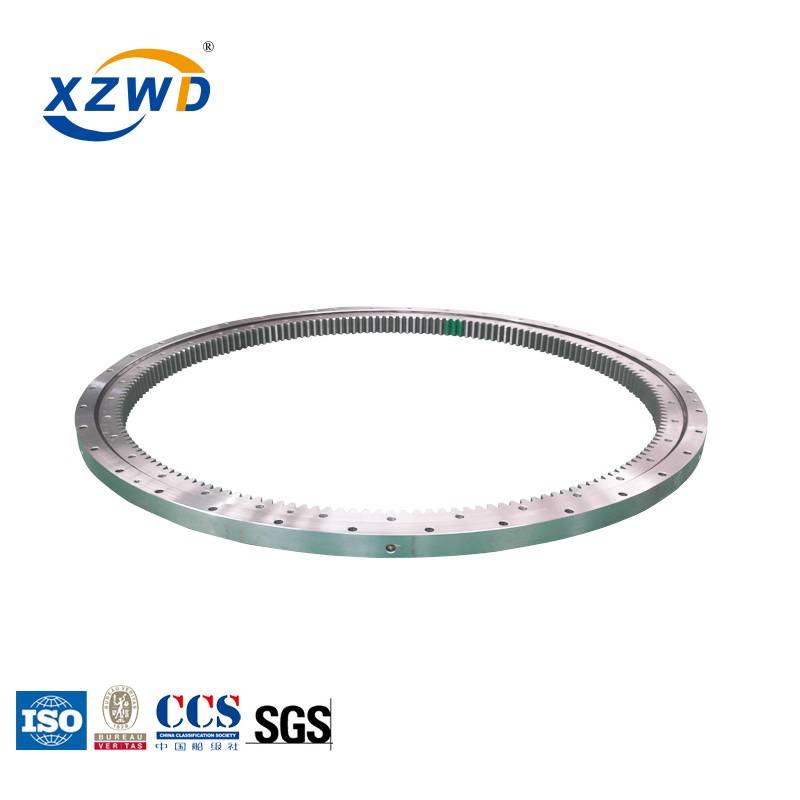

Original Factory Heavy Duty Turntable Bearing - heavy duty turntable bearings with External gear slewing ring – Wanda

Original Factory Heavy Duty Turntable Bearing - heavy duty turntable bearings with External gear slewing ring – Wanda Detail:

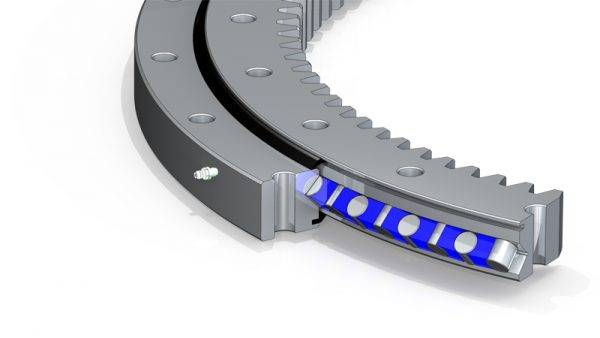

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the slewing bearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of the slewing bearing.

Single-row four-point contact ball slewing ring internal ball machining accuracy and internal raceway machining accuracy is not high, or there are quality defects and lack of lubricating oil in the raceway roller and spacer collision, directly affect the smooth operation of the slewing ring and noise, so when checking the slewing ring defects, sometimes by replacing the ball to reduce the frequency of failure.

Due to the gear under load after a long working time, there will be a small piece of metal or strip of metal near the pitch line, pitting or gnawing metal chips off, the formation of pitting or teeth. The slewing bearing tooth surface pitting with the increase in working time and expanding so that the slewing bearing mesh tooth damage, tower crane rotary noise and impact increases, the cycle of impact down the metal particles and accelerate the wear of the slewing ring tooth surface, forming a vicious cycle. In addition, the manufacturing and assembly of the starter motor in the slewing ring mechanism has its own defects to produce impact jitter, and the engagement process of the drive wheel with the slewing bearing is unstable, which also increases the frequency of jitter and reverberation noise decibels.

If the weld quality is not up to standard, the weld defect needs to be reworked and rewelded. In the repair welding repair will not only produce new welding stress and the flatness of the machined mounting surface will also have a great impact, at the same time the welding current generated in the slewing bearing through the internal rolling body and slewing ring raceway will also cause some damage. In addition, assembly errors in manufacturing assembly, field installation of the pin threading and bolt preload can also produce abnormal noise or chatter if the requirements are not met.

slewing ring main forms are external and internal type, the large and small gears mesh poorly, sometimes tight, sometimes loose, in the slewing ring tooth run out maximum position meshing too tight produce noise. So the manufacturing process is critical. Slewing bearing just left the factory in idling will issue a steel ball rolling uniform sound, which is normal. Such as in the uniform normal ringing accompanied by another abnormally large ringing is abnormal. There are many reasons for the failure.

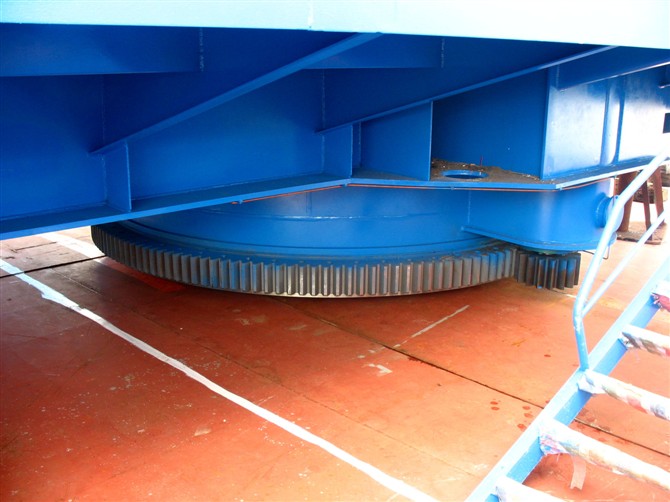

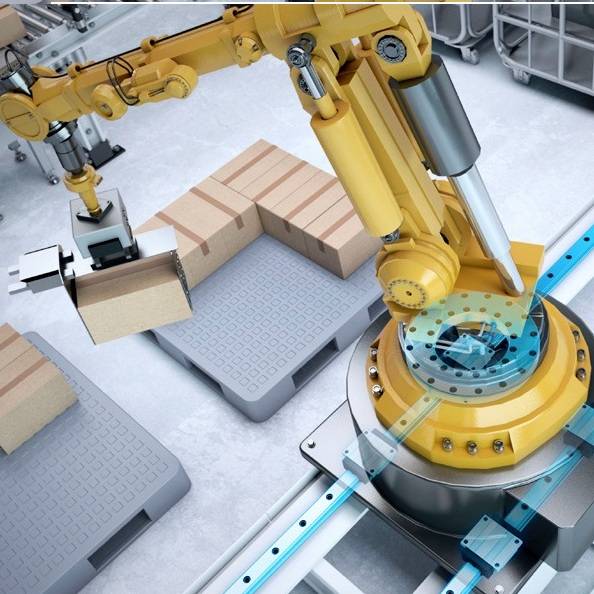

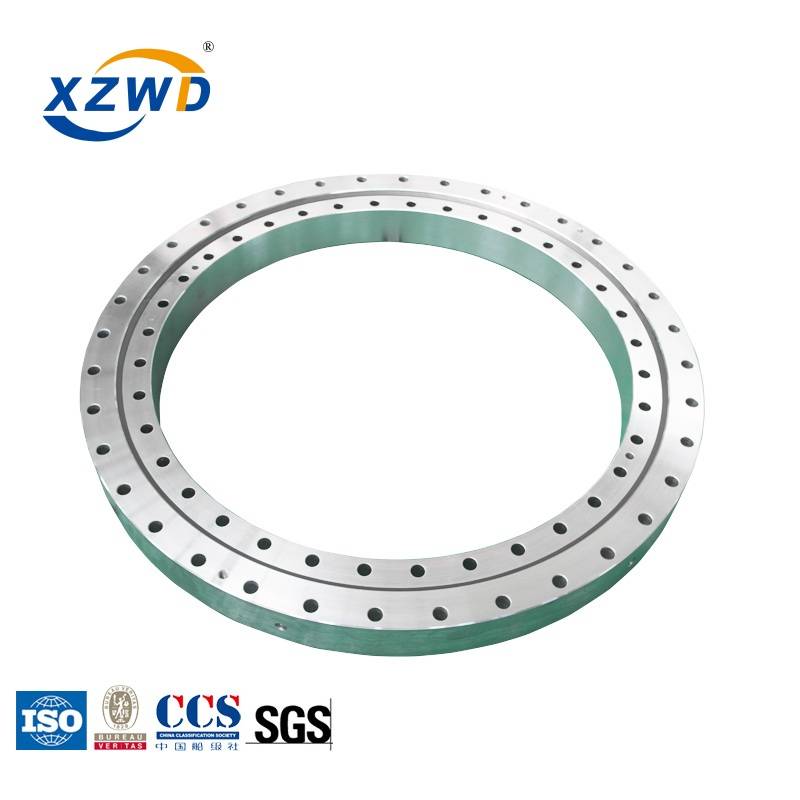

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Original Factory Heavy Duty Turntable Bearing - heavy duty turntable bearings with External gear slewing ring – Wanda , The product will supply to all over the world, such as: Hanover, Sierra Leone, Surabaya, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!