In the current global wave of intelligent manufacturing, the slewing bearing, as the “smart joint” of mechanical equipment, is becoming a core component for promoting industrial automation and intelligence through technological innovation and industrial integration. Its application scenarios have extended from traditional construction machinery to high-end fields such as new energy, robotics, and precision machining, providing key support for intelligent manufacturing.

Intelligent manufacturing covers all scenarios

1. Industrial Robots: The “Precision Dancers” of Core Joints

In the field of industrial robots, rotary bearings are key to achieving multi-axis linkage and high-precision positioning. The turntable bearing products from XZWD are applied in welding and palletizing robots. With micron-level machining accuracy, they ensure smooth movement of robotic arms, achieving a repeat positioning accuracy of ±0.02mm. Their long-life design (with a lifespan exceeding 100,000 hours) and low-noise characteristics enable robots to operate continuously for 24 hours, significantly boosting production efficiency.

2. Automated Production Lines: The “Intelligent Hubs” of Rotary Worktables

In automated production lines for automotive manufacturing, 3C electronics, and other industries, rotary bearings support rotary worktables to achieve precise material transfer. For instance, the lightweight slewing bearings from Xuzhou Wanda Slewing Bearing Co.,Ltd.can dynamically adjust their rotational speed by monitoring load changes in real time, increasing the efficiency of canning production lines by 25%. Their sealed design can withstand erosion from dust and oil, ensuring stable operation in harsh environments.

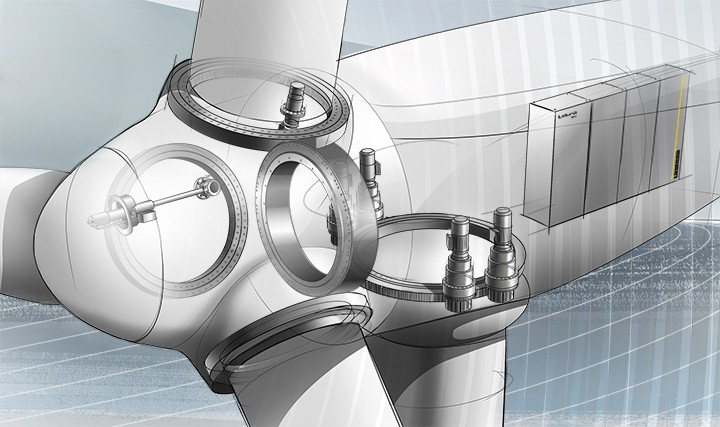

3. New Energy Equipment: The “Stable Foundations” of Green Power

In the wind power sector, slewing bearings are the core of the yaw systems in wind turbine generators. Chinese-produced offshore wind turbine bearings with capacities exceeding 10MW adopt crossed-roller structures, capable of withstanding instantaneous impacts under extreme wind conditions and boasting a lifespan of 25 years. In the solar energy field, slewing bearings and slewing drivedynamically adjust the angles of solar panels, increasing the power generation efficiency of photovoltaic power plants by 15%, serving as a vital technological support for achieving the “dual carbon” goals.

4. Precision Machining and Medical Equipment: The “Invisible Guardians” of High Reliability

In precision equipment such as CNC machine tools and CT scanners, the rotational accuracy of rotary bearings directly affects machining quality. The sealed rotary bearing products developed by Xuzhou Wanda Slewing Bearing Co., Ltd. feature a U-shaped rubber ring and annular groove clamping design, resolving the issue of oil leakage caused by elasticity decay in traditional sealing rubber rings and ensuring long-term stable operation of medical equipment.

In conclusion, the Chinese slewing bearing industry is wielding technological innovation as a spear and application expansion as a shield, playing a pivotal role in global intelligent manufacturing. Looking ahead, with the deep integration of technologies like 5G and AI, these “industrial joints” are bound to inject stronger momentum into the global manufacturing sector, propelling industrial civilization to a higher stage.

Post time: Oct-31-2025