Massive Selection for China Slewing Reducer Manufacturer - XZWD factory supply slewing mechanism use swing bearing – Wanda

Massive Selection for China Slewing Reducer Manufacturer - XZWD factory supply slewing mechanism use swing bearing – Wanda Detail:

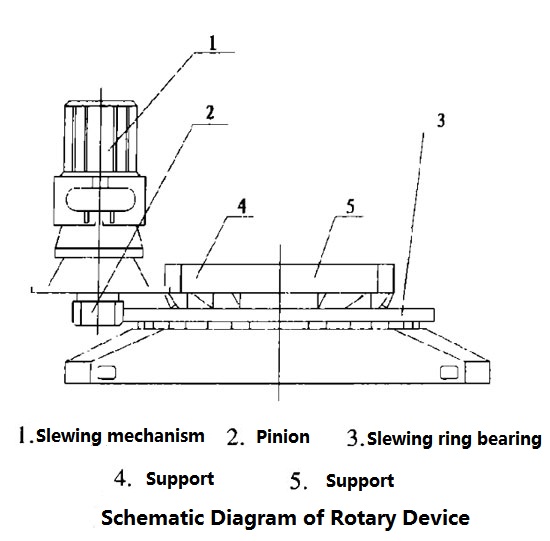

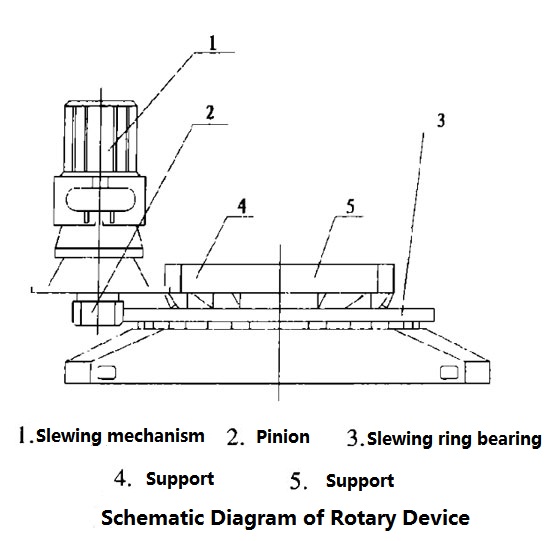

The slewing mechanism is composed of a supporting device, a slewing bearing and a turntable. The slewing bearing is an important force-bearing component. It not only bears the dead weight of the rotating part of the crane, but also bears the vertical force of the lifting load and the force of the tipping moment. During use, there must be wear and tear, and the performance of related mechanical parts will gradually deteriorate or even be damaged.

Common faults of the slewing mechanism mainly include excessive slewing bearing clearance (wild movement), slow movement (weakness) or immobility of the slewing system, abnormal system pressure, and oil leakage. How can I solve a problem?

1. The slewing bearing clearance is too large (open movement)

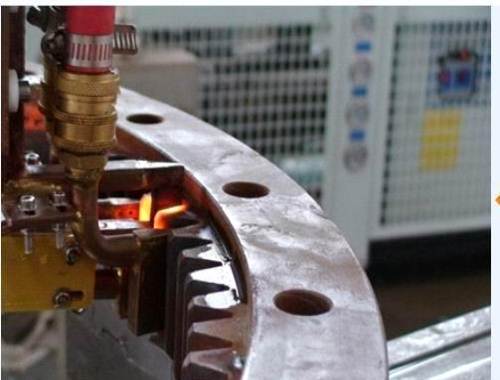

This is because the worm gear, driving gear and slewing ring gear of the slewing reducer are seriously worn. Please check the clearance with a dial indicator. If it is too large, the slewing ring bearing should be disassembled and replaced and related parts replaced.

2. The slewing system moves slowly (weak) or does not move

The hydraulic motor is malfunctioning, the reducer is malfunctioning, there is an overload, the overflow valve, the manual control valve is malfunctioning. Damage to the gear of the slewing reducer, the plunger or bearing of the hydraulic motor is stuck or severely worn, and the output shaft of the hydraulic motor is broken. These problems will cause the slewing system to move slowly or not move. Check and adjust the faulty parts and replace them if necessary. If it is overloaded, check the lifting weight again.

3. System pressure is abnormal

4. Oil spill

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Massive Selection for China Slewing Reducer Manufacturer - XZWD factory supply slewing mechanism use swing bearing – Wanda , The product will supply to all over the world, such as: Paraguay, Macedonia, kazakhstan, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.