Manufacturer for Slewing Drive For Solar Tracker - High quality Industrial Robotic Arm use Slew Drive – Wanda

Manufacturer for Slewing Drive For Solar Tracker - High quality Industrial Robotic Arm use Slew Drive – Wanda Detail:

High quality Industrial Robotic Arm use Slew Drive

Slew drive delivers dependable and maintenance-free performance in industrial applications. It could be used in Robotic arm. Manufacturing plants and industrial machinery use slewing drives to power movement and control rotational torque. Mechanical equipment and robotics rely on slewing drives for positioning accuracy and consistent performance.

Robotic arms are mechanical devices that have joints that can bend and rotate. They are driven by computer-controlled electric motors. Tools can be fitted to the ‘hand’ end of the arms, and the computer programmed to make them perform different tasks, such as cutting, drilling, welding, and painting. They are also used for dangerous tasks such as handling radioactive materials or unexploded bombs.

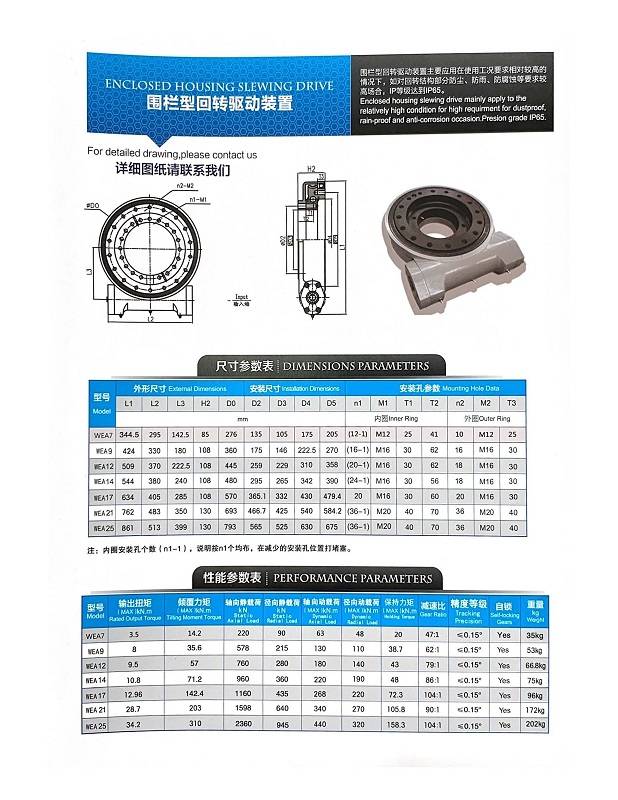

With the design of curved tooth structure, WEA Slewing drive has better anti-fatigue and bonding ability, which is suitable for heavy-duty, medium-speed applications, it is suitable for Robotic Arm application.

You can see the catalogue for the WEA Slewing drive.

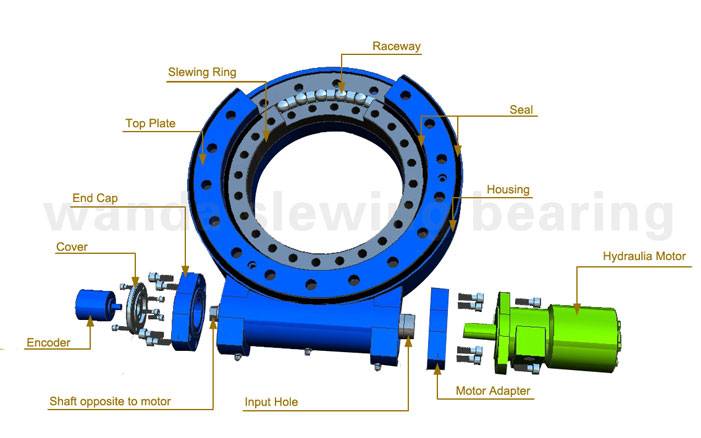

The slewing drive is a gearbox that can safely hold radial and axial loads, as well as transmit a torque for rotating. The rotation can be in a single axis, or in multiple axes together. Slewing drives are made by manufacturing gearing, bearings, seals, housing, motor and other auxiliary components and assembling them into a finished gearbox.

The slewing drive uses precision kinematics to provide a large proportion of single-stage gearing. Bearings and gears are assembled into a small, self-contained, and ready-to-install case to optimize weight and performance. XZWD slewing bearing co.,ltd as an experienced slew drive manufacturer, we have the capability to provide high quality slew drives.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for Manufacturer for Slewing Drive For Solar Tracker - High quality Industrial Robotic Arm use Slew Drive – Wanda , The product will supply to all over the world, such as: Macedonia, Puerto Rico, Hanover, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!