Factory wholesale Trailer Slewing Turntable - XZWD Slewing bearing factory high quality teeth quenched turntable bearing – Wanda

Factory wholesale Trailer Slewing Turntable - XZWD Slewing bearing factory high quality teeth quenched turntable bearing – Wanda Detail:

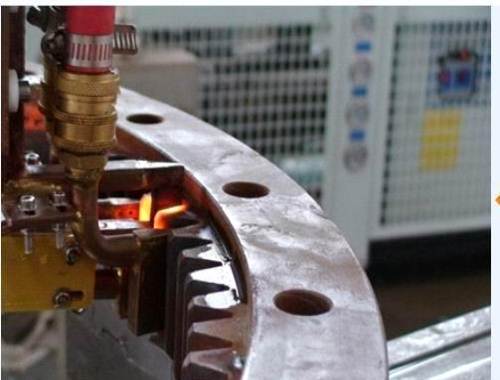

Tooth heat treatment is an important process in the processing of slewing bearings, and the application of some products requires relatively high hardness of the tooth surface. Through high-frequency induction hardening, the bearing tooth surface can be hardened, effectively increasing the strength and service life of the product. We can perform single tooth quenching or overall quenching according to the modulus and product design requirements.

When continuous induction heating quenching is performed on the raceways of the slewing ring gear and the rolling ring, attention should be paid to the connection between the starting point and the end point of the slewing ring quenching. If the slewing bearing quenching belt overlaps, cracks are likely to occur. For this reason, a certain distance should be maintained at the head-to-tail quenching connection of the slewing ring.

XZWD slewing bearing co.,ltd can quench the teeth according to customer requirements.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for Factory wholesale Trailer Slewing Turntable - XZWD Slewing bearing factory high quality teeth quenched turntable bearing – Wanda , The product will supply to all over the world, such as: Senegal, Azerbaijan, Frankfurt, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.