Factory wholesale Machine Slewing Bearing - three row roller slewing bearing – Wanda

Factory wholesale Machine Slewing Bearing - three row roller slewing bearing – Wanda Detail:

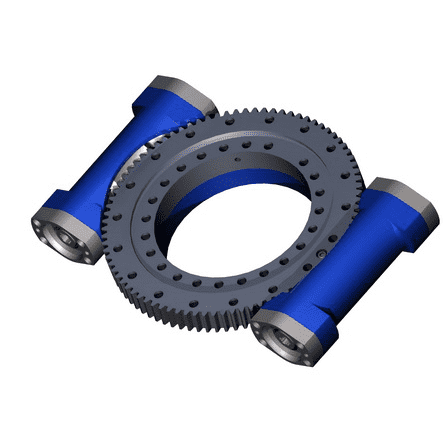

Three row roller slewing ring bearing

Three row roller slewing bearing application

Three row roller slewing bearing with the largest load capacity.Due to thr large size in axial and radial dimension & the solid structure,it is specially suitable for the heavy duty machinery such as wheeled excavator,wheeled crane,ship crane,ladle turrest and the heavy duty mobile crane etc.

Port Crane used slewing bearing

Inner gear three row roller slewing bearing is widely used for port crane.XZWD can also supply CCS certificate and BV certificate.

Ship unloaders used slewing bearing

External gear three row roller slewing bearing is used for ship unloaders.We can do the slewing bearing size from 150~5000mm.

Ladle turret used slewing bearing

NON-gear type three row roller slewing bearing.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Factory wholesale Machine Slewing Bearing - three row roller slewing bearing – Wanda , The product will supply to all over the world, such as: Tunisia, Hanover, Barcelona, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!