factory low price Lazy Susan Bearing Mechanism - Truck Crane Used Slewing Ring Bearing – Wanda

factory low price Lazy Susan Bearing Mechanism - Truck Crane Used Slewing Ring Bearing – Wanda Detail:

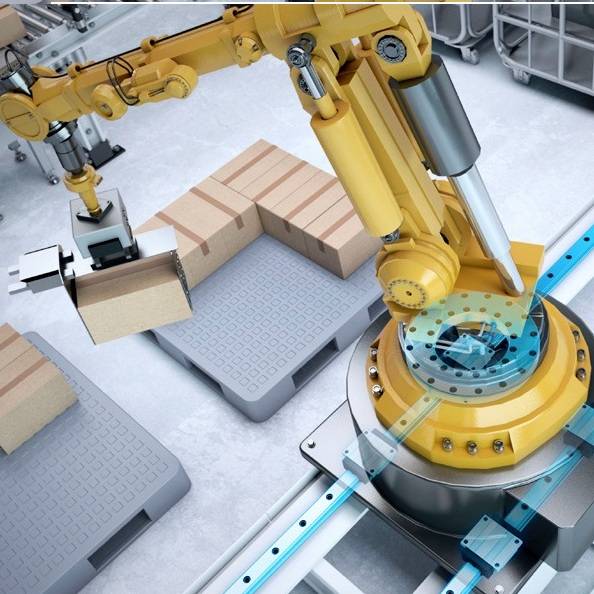

Truck Crane Used Slewing Ring Bearing

The crane is a kind of mechanical equipment that works in an intermittent and repetitive manner, and realizes vertical lifting and horizontal movement of heavy objects hanging on hooks or other fetching devices within a certain space.

The most common mobile cranes include common truck cranes, tire cranes, crawler cranes, all-terrain cranes and off-road cranes.

Components of a crane

Various types of engineering cranes are usually composed of four parts: working mechanism, metal structure, power plant and control system.

Following we will introduce the working mechanism of the crane. It includes four parts: lifting mechanism, luffing mechanism, slewing mechanism and walking mechanism.

1. Lifting mechanism

The lifting structure is composed of prime mover, drum, wire rope, pulley block and hook. Lifting methods are mechanical and hydraulic transmission.

2. Luffing mechanism

Crane swing refers to changing the distance between the center of the hook and the axis of the crane’s slewing center. The form of luffing mechanism depends on the type of mobile crane boom. For a truss crane with a constant length, the luffing mechanism uses a wire rope luffing mechanism. The luffing mechanism of the mobile crane of the telescopic boom uses a hydraulic cylinder luffing mechanism.

3. Slewing mechanism

The slewing mechanism consists of a drive device and a slewing bearing. The slewing bearing of a mobile crane usually adopts the single row four point contact slewing bearing.

4. Walking mechanism

The walking mechanism of the mobile crane is the chassis of the crane. The wheeled crane uses a general or special car chassis, or a chassis specially designed for the crane. The crawler crane uses a crawler chassis. The walking mechanisms of tower and bridge cranes are generally specially designed running tracks.

XZWD Slewing bearing company is professional producer which specialized in Slewing bearing and slewing drive for more than 20 years. XZWD slewing bearing could be used for Various types of cranes. You can send email to get more details.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

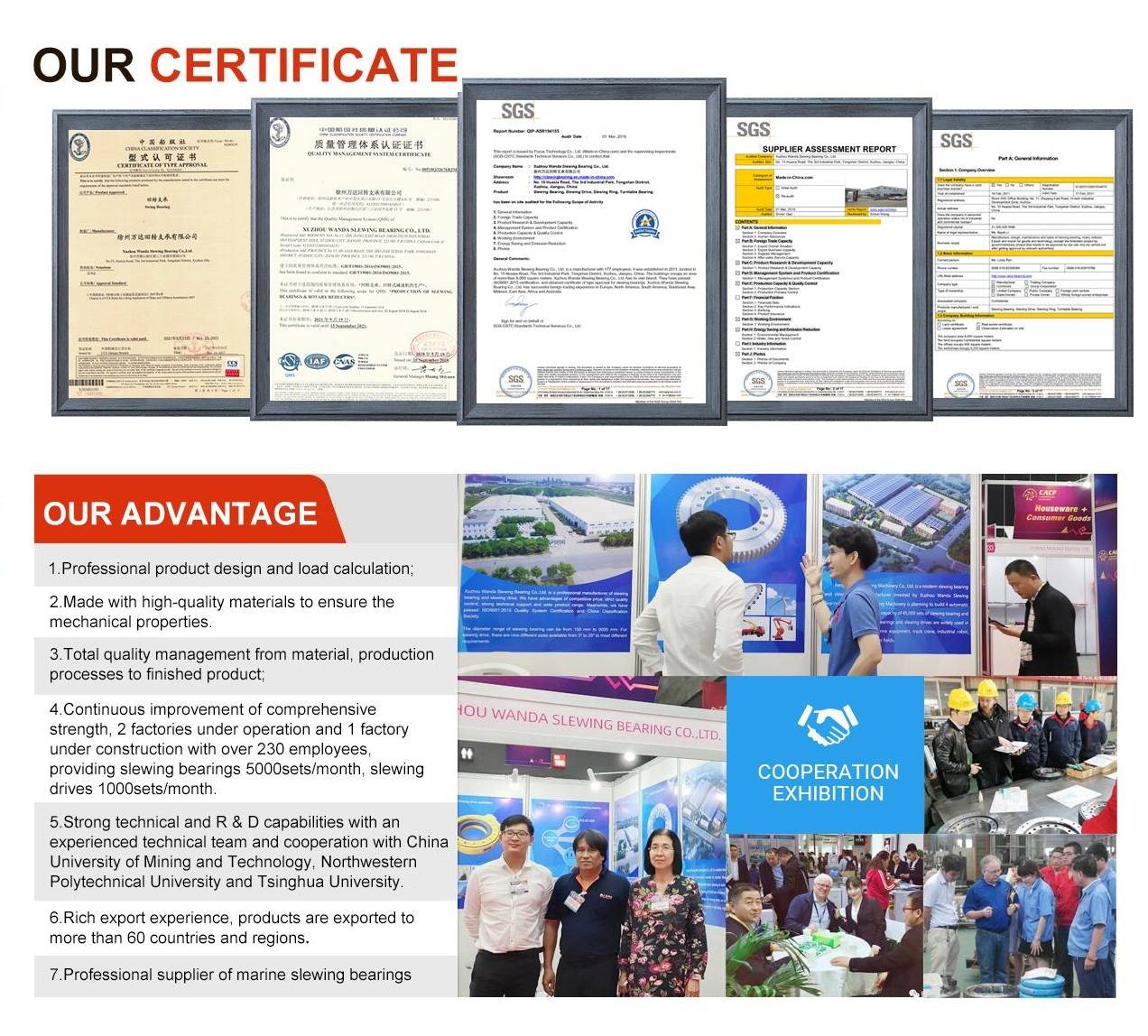

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for factory low price Lazy Susan Bearing Mechanism - Truck Crane Used Slewing Ring Bearing – Wanda , The product will supply to all over the world, such as: Uruguay, Casablanca, Guinea, Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.