factory low price Lazy Susan Bearing Mechanism - double row different ball size slewing bearing without gear 020.25.500 – Wanda

factory low price Lazy Susan Bearing Mechanism - double row different ball size slewing bearing without gear 020.25.500 – Wanda Detail:

Slewing bearing is a kind of large bearing which can bear comprehensive load. It can bear large axial, radial load and overturning moment at the same time. Generally, slewing bearing is equipped with mounting hole, internal or external gear, lubricating oil hole and sealing device, which makes the design of main engine compact, easy to guide and easy to maintain. There are four series of slewing bearing: toothless, external and internal four point contact ball bearing, double row angular contact ball bearing, cross cylindrical roller bearing, cross tapered roller bearing and three row cylindrical roller composite bearing. Among them, four point contact ball bearing has higher static load capacity, cross cylindrical roller has higher dynamic load capacity, and cross tapered roller bearing has higher pre load capacity Interference can make the bearing have greater support rigidity and rotation accuracy. Due to the increase of bearing capacity, the three row cylindrical roller combined bearing leads to the bearing height, and various forces are borne by different raceways respectively. Therefore, the bearing diameter can be greatly reduced under the same stress, so the main engine is more compact. It is a slewing bearing with high bearing capacity. Slewing bearing is widely used in large-scale slewing device of hoisting machinery, mining machinery, construction machinery, port machinery, ship machinery, high-precision radar machinery and missile launcher. At the same time, we can also design, develop and produce all kinds of special structure slewing bearing according to the specific requirements of users. Basic structure of slewing bearing.

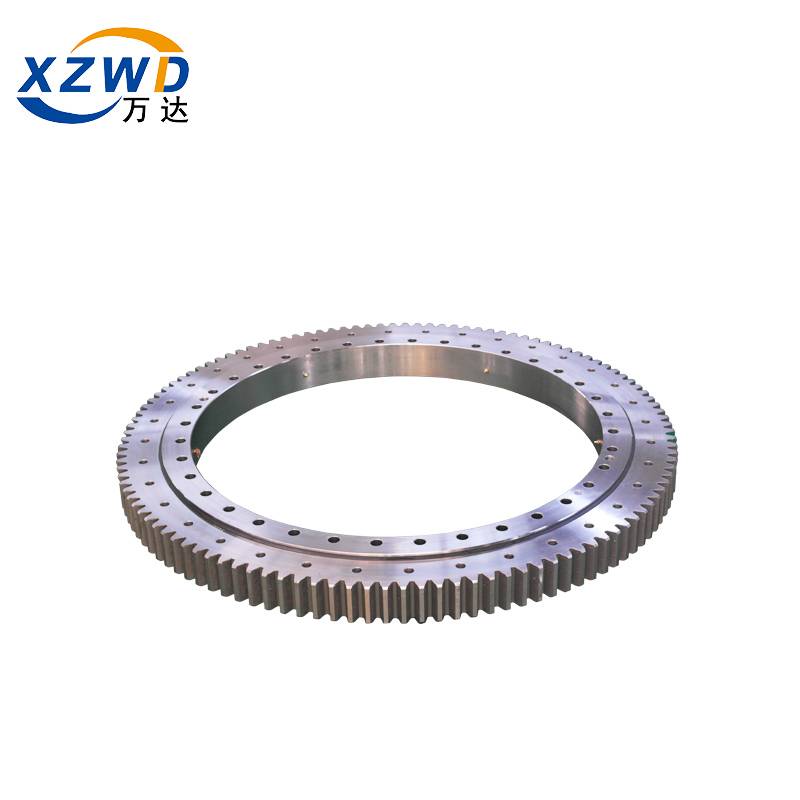

The double volleyball type turntable bearing has three races. The steel ball and isolation block can be directly discharged into the upper and lower raceways. Two rows of steel balls with different diameters are arranged according to the stress condition. This kind of open assembly is very convenient. The bearing angles of the upper and lower arc raceways are 90 ° and can bear large axial force and overturning moment. When the radial force is greater than 0.1 times of the axial force, the raceway must be specially designed. The axial and radial dimensions of double row spherical slewing bearing with different diameters are relatively large and the structure is tight. It is especially suitable for tower crane, truck crane and other loading and unloading machinery with medium or above diameter.

There are many forms of slewing bearing, but their structure composition is basically the same. Outer ring (toothed or toothless),. Sealing belt,. Rolling element (ball or roller), oil nozzle, plug, plug pin, inner ring (toothed or toothless), spacer or cage, mounting hole (threaded or smooth).

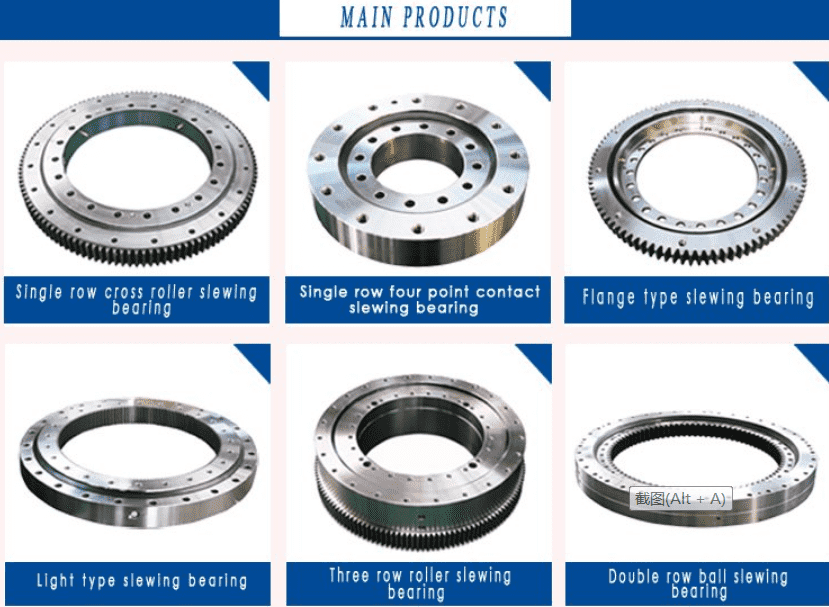

According to different structural types, turntable bearings can be divided into four point contact ball turntable bearings, cross cylindrical (tapered) roller turntable bearings, double row four point ball turntable bearings, double row reduced diameter spherical slewing bearings, ball roller combinations and three rows of cylindrical roller combined turntable bearings. The above bearings are divided into toothless ones according to whether they are toothed or not and the distribution of teeth There are different structures, such as type, external tooth type or internal tooth type.

According to the different structural characteristics of turntable bearing, it can meet the requirements of working host under different load conditions. Among them, four point contact ball slewing bearing has higher dynamic load capacity, cross cylindrical roller slewing bearing has higher static load capacity, three row cylindrical roller combined turntable bearing can lead the increase of bearing capacity to the bearing height direction, and various loads are borne by different raceways and roller groups, so the diameter of raceway is greatly reduced under the same stress condition, With the characteristics of making the main engine more compact, it is a high bearing capacity turntable bearing.

Slewing bearing is a kind of large bearing which can bear comprehensive load. It can bear large axial, radial load and overturning moment at the same time. Generally, slewing bearing is equipped with mounting hole, internal or external gear, lubricating oil hole and sealing device, which makes the design of main engine compact, easy to guide and easy to maintain. There are four series of slewing bearing: toothless, external and internal four point contact ball bearing, double row angular contact ball bearing, cross cylindrical roller bearing, cross tapered roller bearing and three row cylindrical roller composite bearing. Among them, four point contact ball bearing has higher static load capacity, cross cylindrical roller has higher dynamic load capacity, and cross tapered roller bearing has higher pre load capacity Interference can make the bearing have greater support rigidity and rotation accuracy. Due to the increase of bearing capacity, the three row cylindrical roller combined bearing leads to the bearing height, and various forces are borne by different raceways respectively. Therefore, the bearing diameter can be greatly reduced under the same stress, so the main engine is more compact. It is a slewing bearing with high bearing capacity. Slewing bearing is widely used in large-scale slewing device of hoisting machinery, mining machinery, construction machinery, port machinery, ship machinery, high-precision radar machinery and missile launcher. At the same time, we can also design, develop and produce all kinds of special structure slewing bearing according to the specific requirements of users.

Product detail pictures:

Related Product Guide:

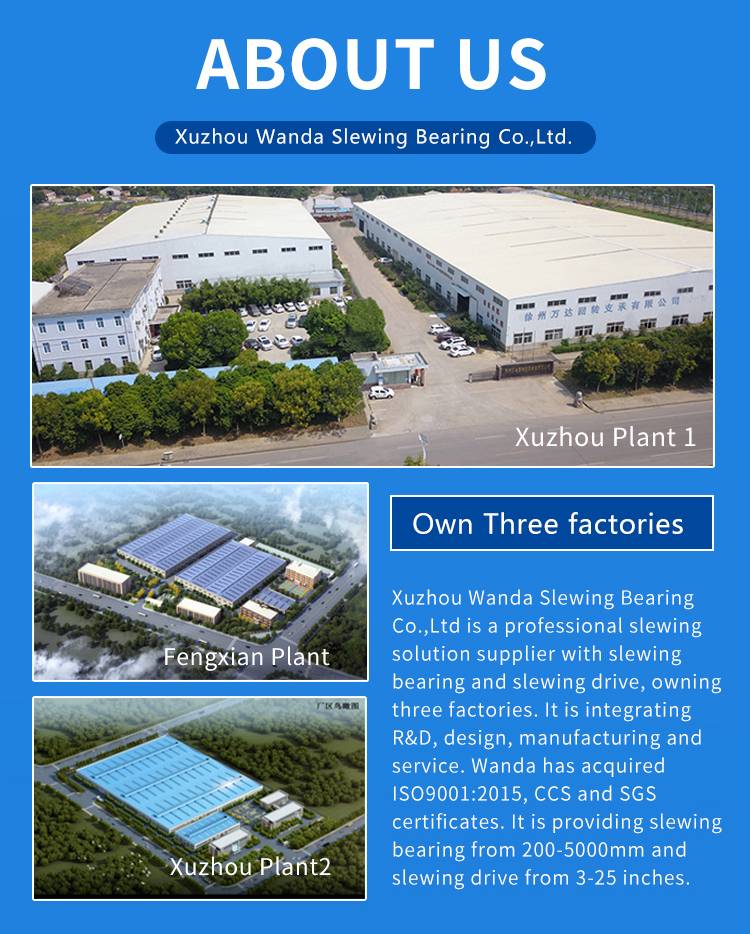

Car parking system used slewing bearing

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for factory low price Lazy Susan Bearing Mechanism - double row different ball size slewing bearing without gear 020.25.500 – Wanda , The product will supply to all over the world, such as: Chile, Manila, UAE, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.