8 Year Exporter Roller Slewing Ring - Non-Geared Three row Roller Slewing Bearing for Heavy Machinery – Wanda

8 Year Exporter Roller Slewing Ring - Non-Geared Three row Roller Slewing Bearing for Heavy Machinery – Wanda Detail:

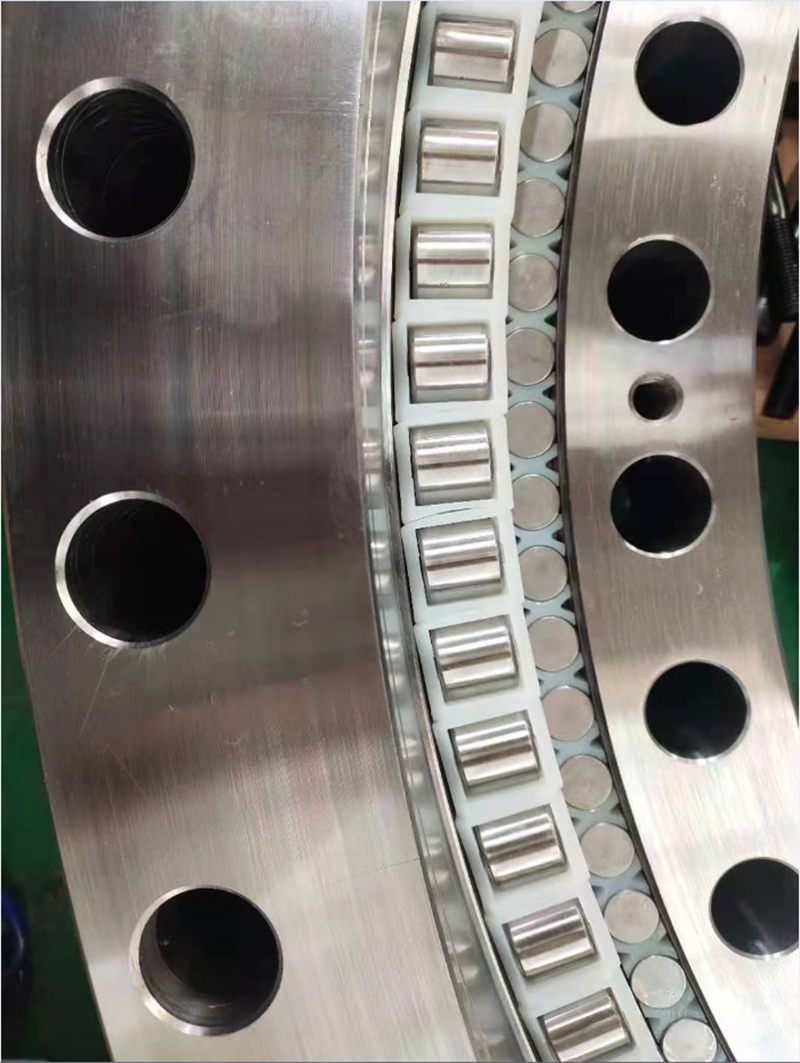

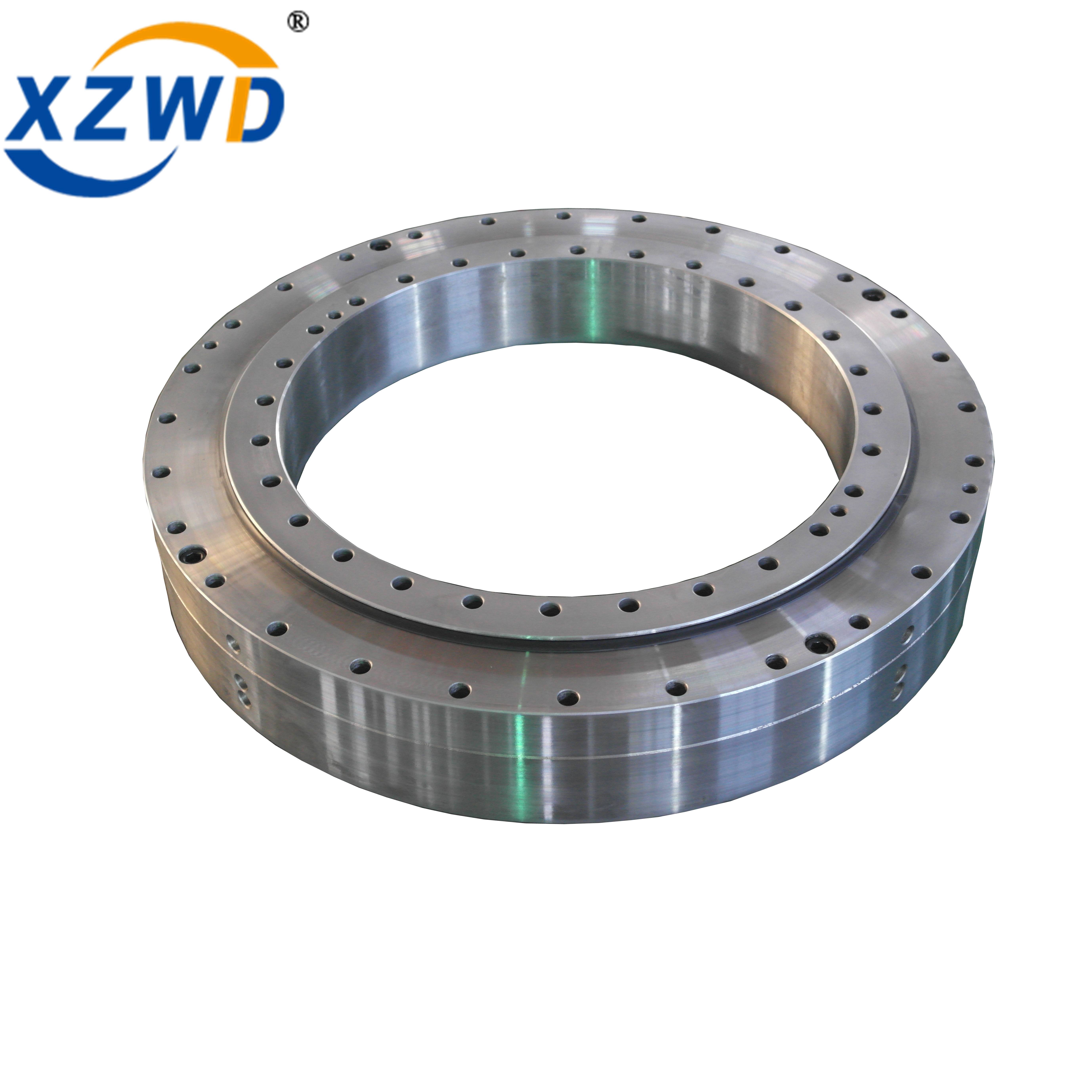

There are three rows of slewing bearings with rollers of different diameters as rolling elements. It is composed of three seat ring, three groups of rollers and spacers,

connecting bolts and dustproof ring. According to differnet load conditions, the upper row of rollers has the largest size, and the lateral rollers have the smallest size.

The upper and lower row of rolling elements bear axial force and verturning moment, while the lateral rolling elements bear radial force. It is a slewing bearing with

the largest bearing capacity. Mostly used in heavy construction machinery.

We also can use the steel cage or copper cage for the slewing bearing, and it used for fast speed.

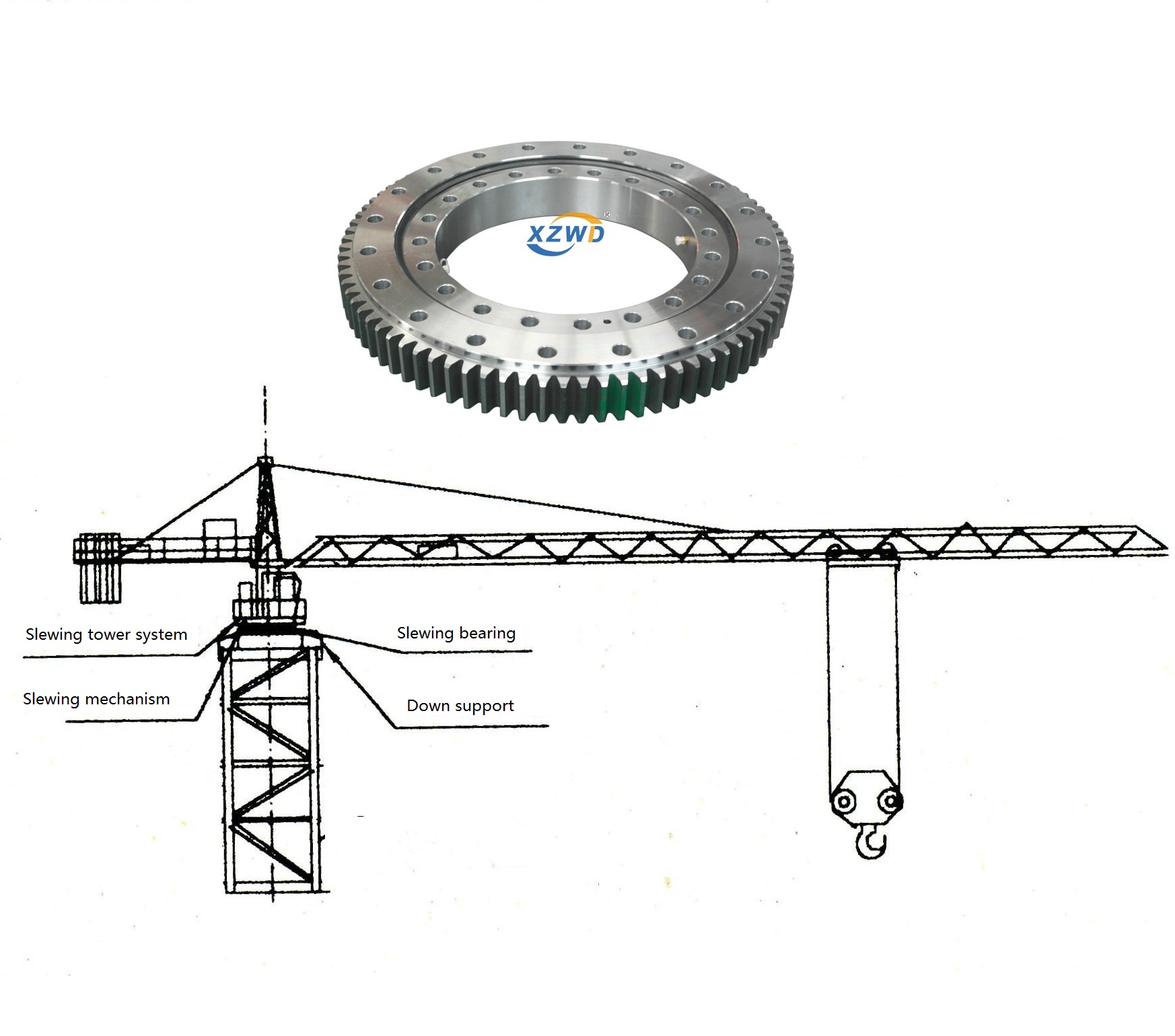

For slewing bearing, it have three type of teet:

1. Outernal gear slewing bearing

2. Internal gear slewing bearing

3. Non-geared slewing bearing

Product detail pictures:

Related Product Guide:

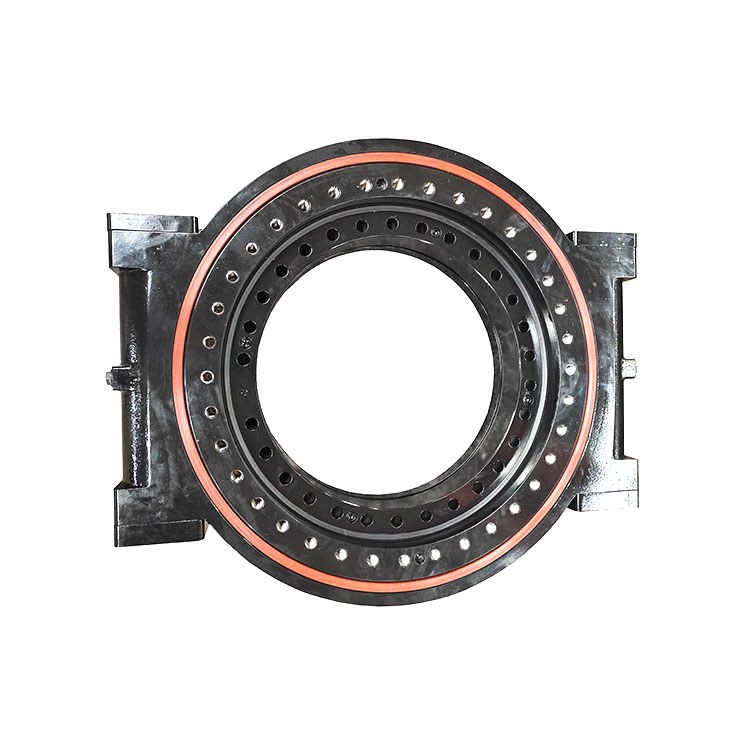

Car parking system used slewing bearing

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for 8 Year Exporter Roller Slewing Ring - Non-Geared Three row Roller Slewing Bearing for Heavy Machinery – Wanda , The product will supply to all over the world, such as: Ecuador, Curacao, Uruguay, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.