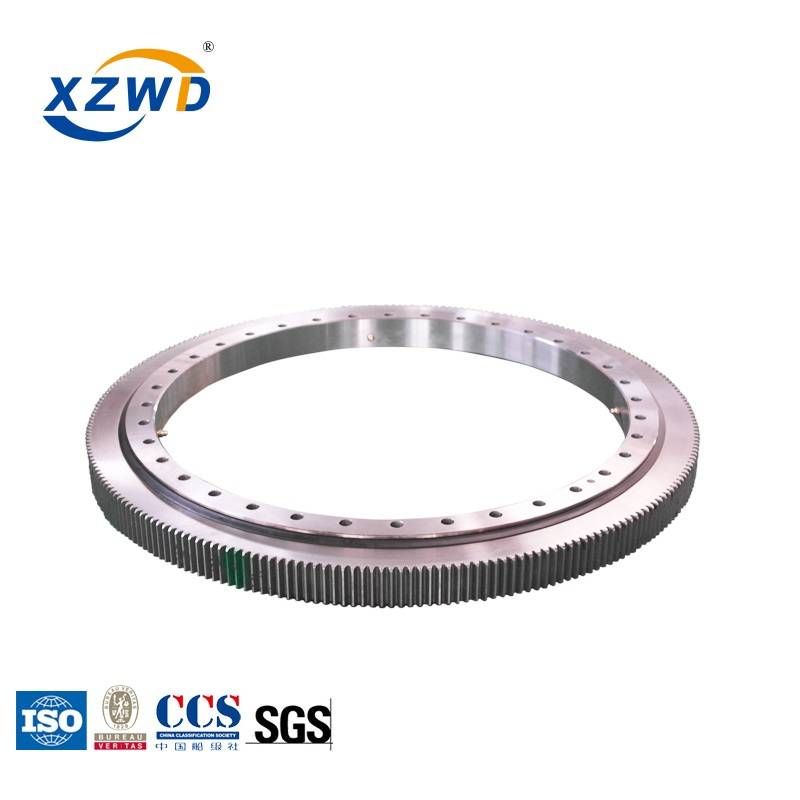

2020 wholesale price Quiet Lazy Susan Bearing - XZWD single row ball four point contact ball slewing bearing grease – Wanda

2020 wholesale price Quiet Lazy Susan Bearing - XZWD single row ball four point contact ball slewing bearing grease – Wanda Detail:

>> Product type

1.Single Row Four Point Contact Ball Slewing Bearings.

2.Single Row Crossed Roller Slewing Bearings

3Double Row Ball Slewing Bearings

4.Three Row Roller Slewing Bearings

5.Thin Section Slewing bearings(Light type).

6.Thin Section Slewing Bearings (Flange type)

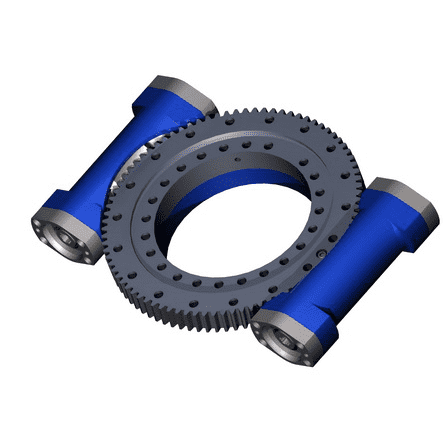

Slewing ring can bear axial, radial load and tilting moment load simultaneously. It can be combined with pinion, planetary gearbox and motors…

We have strict production schedule to assure the delivery time, the production schedule as below:

A. Forging purchase period: 15-20 days

B. Production process:

1. Rough turning: 2-3 days

2. Raceway heat treatment: 2 days

3. Fine turning: 2 days

4. Gear cutting: 4-5 days

5. Drilling: 2-3 days

6. Final turning: 2 days

7. Assembling and Inspection: 2 days

C. Packing and delivery to Port: 3-5 days

Totally about 40-50days

The products are widely used in engineering machinery, building machinery, metallurgical and mining machinery, shipping port machinery, environmental protection machinery, light industry machinery, petroleum chemical machinery, engineering vehicle, war industry equipment and so on.

XZWD Slewing ring Co.,Ltd. is a professional manufacturer and exporter of slewing bearing,slewing drives.

XUZHOU WANDA SLEWING RING CO.,LTD. is the leading manufacturer of slewing bearings (200~4500MM).

XZWD slewing ring can do the seamless slewing bearing.Furthermore,WANDA SLEWING BEARING CO.,LTD. is a well-known manufacturer of Slewing drive from 3″ to 25″.

XZWD delivers custom-engineered solutions to customers in 34 countries,especially in the Europe and USA market.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2008

| No | External gear | Dimensions (mm) | Mounting Dimensions (mm) | Structural Dimension (mm) | Gear data | Gear force10^4 KN | weight kg |

||||||||||||||||

| D | d | H | D1 | D2 | n | Φ | dm | L | n1 | D3 | d1 | H1 | h | b | x | M | De | z | N | T | |||

| 1 | 011.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 40 | 0 | 3 | 300 | 98 | 1.5 | 2.1 | 24 |

| 2 | 011.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 40 | 0 | 3 | 321 | 105 | 1.5 | 2.1 | 25 |

| 3 | 011.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 40 | 0 | 4 | 352 | 86 | 2.1 | 2.8 | 30 |

| 4 | 011.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 40 | 0 | 4 | 384 | 94 | 1.5 | 2.8 | 34 |

| 5 | 011.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 50 | 0 | 5 | 435 | 85 | 2.9 | 4.4 | 52 |

| 6 | 011.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 50 | 0 | 5 | 475 | 93 | 2.9 | 4.4 | 59 |

| 7 | 011.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 50 | 0 | 6 | 528 | 86 | 3.5 | 5.3 | 69 |

| 8 | 011.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 50 | 0 | 6 | 576 | 94 | 3.5 | 5.3 | 76 |

| 9 | 011.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 499 498 | 70 | 10 | 60 | 0.5 | 5 | 629 | 123 | 3.7 | 5.2 | 85 |

| 012.30.500 | 6 | 628.8 | 102 | 4.5 | 6.2 | ||||||||||||||||||

| 10 | 011.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 559 558 | 70 | 10 | 60 | 0.5 | 5 | 689 | 135 | 3.7 | 5.2 | 95 |

| 012.25/30.560 | 6 | 688.8 | 112 | 4.5 | 6.2 | ||||||||||||||||||

| 11 | 011.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 629 628 | 70 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 4.5 | 6.2 | 110 |

| 012.25/30.630 | 8 | 774.4 | 94 | 6 | 8.3/8.2 | ||||||||||||||||||

| 12 | 011.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 709 708 | 70 | 10 | 60 | 0.5 | 6 | 850.8 | 139 | 4.5 | 6.2 | 120 |

| 012.30.710 | 8 | 854.4 | 104 | 6 | 8.9/8.3 | ||||||||||||||||||

| 13 | 011.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 966.4 | 118 | 8 | 11.1 | 220 |

| 012.40.800 | 10 | 968 | 94 | 10 | 14.1/14 | ||||||||||||||||||

| 14 | 011.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 1062.4 | 130 | 8 | 11.1 | 240 |

| 012.40.900 | 10 | 1068 | 104 | 10 | 14 | ||||||||||||||||||

| 15 | 011.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 1188 | 116 | 10 | 14 | 270 |

| 012.30/40.1000 | 12 | 1185.6 | 96 | 12 | 16.7 | ||||||||||||||||||

| 16 | 011.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 80 | 0.5 | 10 | 1298 | 127 | 10 | 14 | 300 |

| 012.30/40.1120 | 12 | 1305.6 | 106 | 12 | 16.7 | ||||||||||||||||||

| 17 | 011.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 90 | 0.5 | 12 | 1449.6 | 118 | 13.5 | 18.8 | 420 |

| 012.35/45.1250 | 14 | 1453.2 | 101 | 15.8 | 21.9 | ||||||||||||||||||

| 18 | 011.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 90 | 0.5 | 12 | 1605.6 | 131 | 13.5 | 18.8 | 480 |

| 012.35/45.1400 | 14 | 1607.2 | 112 | 15.5 | 21.9 | ||||||||||||||||||

| 19 | 011.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 90 | 0.5 | 14 | 1817.2 | 127 | 15.8 | 21.9 | 550 |

| 012.35/45.1600 | 16 | 1820.8 | 111 | 18.1 | 25 | ||||||||||||||||||

| 20 | 011.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1801 1802 |

1798 | 100 | 10 | 90 | 0.5 | 14 | 2013.2 | 141 | 15.8 | 21.9 | 610 |

| 012.35/45.1800 | 16 | 2012.8 | 123 | 18.1 | 25 | ||||||||||||||||||

| 21 | 011.40/60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2001 2002 |

1998 | 132 | 12 | 120 | 0.5 | 16 | 2268.8 | 139 | 24.1 | 33.3 | 1100 |

| 012.40/60.2000 | 18 | 2264.4 | 123 | 27.1 | 37.5 | ||||||||||||||||||

| 22 | 011.40/60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2241 2242 |

2238 | 132 | 12 | 120 | 0.5 | 16 | 2492.8 | 153 | 24.1 | 33.3 | 1250 |

| 012.40/60.2240 | 18 | 2498.4 | 136 | 27.1 | 37.5 | ||||||||||||||||||

| 23 | 011.40/60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2501 2502 |

2498 | 132 | 12 | 120 | 0.5 | 18 | 2768.4 | 151 | 27.1 | 37.5 | 1400 |

| 012.40/60.2500 | 20 | 2776 | 136 | 30.1 | 41.8 | ||||||||||||||||||

| 24 | 011.40/60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 120 | 0.5 | 18 | 3074.4 | 168 | 27.1 | 37.5 | 1600 |

| 012.40/60.2800 | 20 | 3076 | 151 | 30.1 | 41.8 | ||||||||||||||||||

| 25 | 011.50/75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 150 | 0.5 | 20 | 3476 | 171 | 37.7 | 52.2 | 2800 |

| 012.50/75.3150 | 22 | 3471.6 | 155 | 41.5 | 57.4 | ||||||||||||||||||

>>Note

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple’s location can be change according to the user’s application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. “K” is addendum reduction coefficient.

XZWD Slewing Bearing Co.,Ltd. is a slewing bearing manufacturer specializing in standard and non-standard slewing bearing.Over the years, we supplied high quality product & good service to every user and gain good credit.We have strict quality control system in our own factory,meanwhile, we have passed ISO9001-2008

>> Applications

wind generator, Marine Crane, Offshore Crane,Harbor mobile crane, Ferris wheel,stacker,Unloader,Construction Machinery,Ladle turret,shield machine,radar and so on

>> Advantages

1. We can supply various size slewing ring bearings.

2. Type: Non-teeth, internal teeth, external teeth

3. Diameter range: 200mm—–4500mm, Weight range: 20kg——–5100kg

4. Design and manufacture according to customer needs, OEM bearing.

5. High quality bearing, competitive price, prompt delivery and best services.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for 2020 wholesale price Quiet Lazy Susan Bearing - XZWD single row ball four point contact ball slewing bearing grease – Wanda , The product will supply to all over the world, such as: Congo, Algeria, Kazakhstan, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!