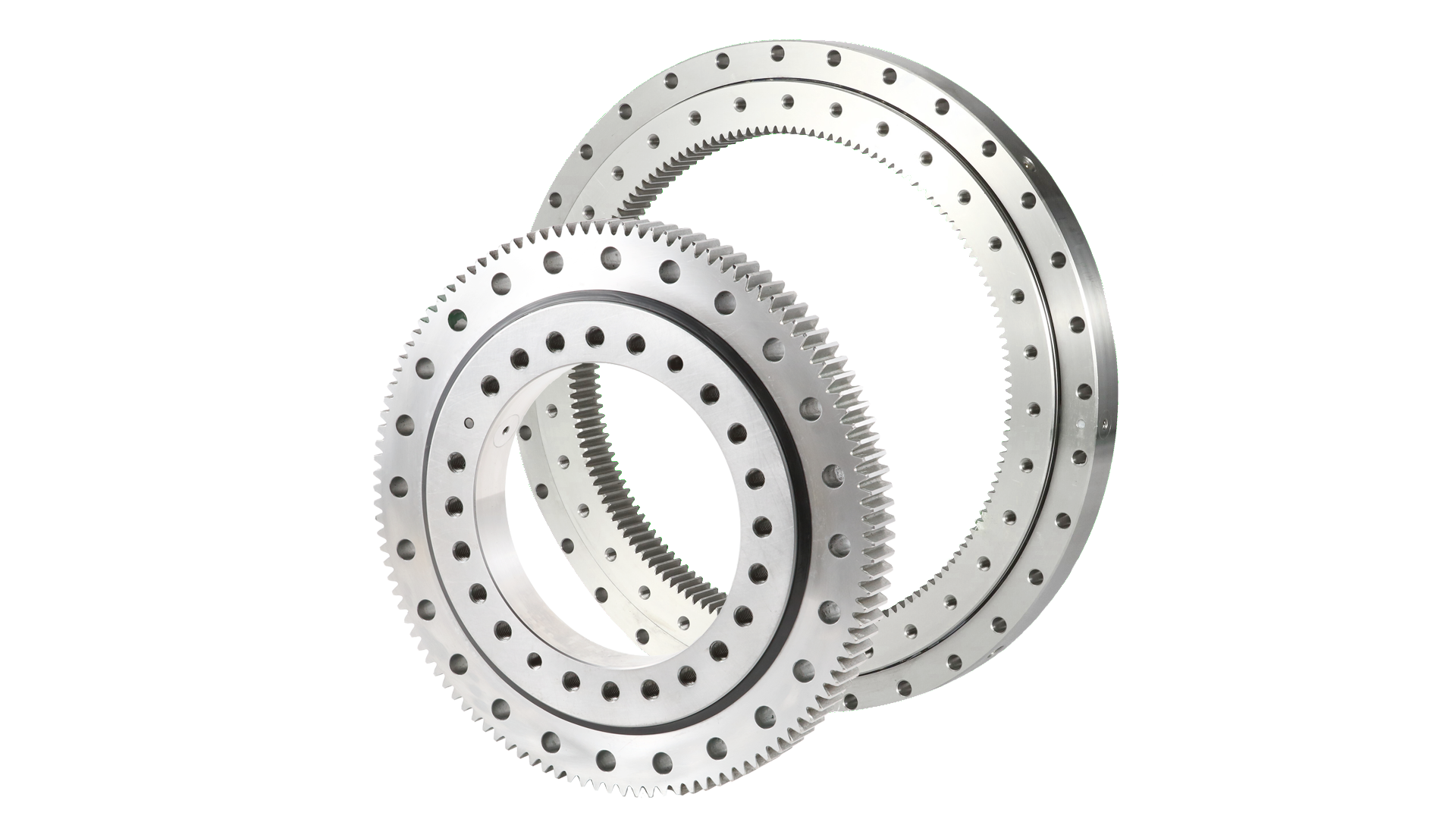

2020 Latest Design Excavator Slewing Gear - Single-row cross-roller slewing ring with external gear 111 series – Wanda

2020 Latest Design Excavator Slewing Gear - Single-row cross-roller slewing ring with external gear 111 series – Wanda Detail:

The single-row cross-roller slewing ring is also composed of two inner and outer rings, with compact structure, high manufacturing precision, light weight and small assembly clearance. The inner ring and the outer ring are connected by rollers, the rollers are arranged in a 1:1 cross, which can bear axial force, tilting moment and larger radial force at the same time. The structure of the cross roller bearing itself is a line contact, which can also be understood as a surface contact, and the line surface contact of the crossed round roller bearing is front, back and left, ensuring the stability of the entire layout.

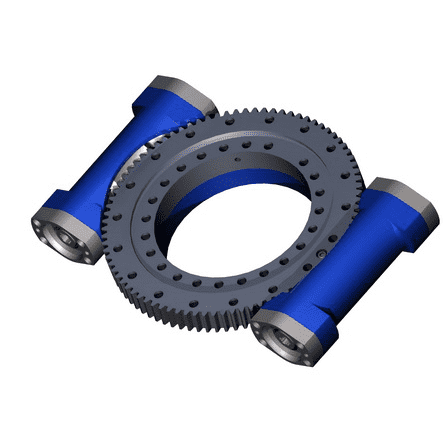

It is widely used in lifting and transportation, military products, medical equipment, bucket wheel machines, park amusement machines, filling machines etc, which play a very important role in construction machinery products.

XZWD slewing bearing 111 series are externally toothed single-row cross roller slewing bearings with teeth on the outer ring, which are generally driven by pinions to achieve a transmission effect. Please see the following table for specific parameters:

| No | External gear DL mm |

Dimensions | Mounting Dimension | Structural Dimension | Gear Data | Gear circumferential force | weight kg |

||||||||||||||||

| D mm |

d mm |

H mm |

D1 mm |

D2 mm |

n | mm | dm mm |

L mm |

n1 mm |

D3 mm |

d1 mm |

H1 mm |

h mm |

b mm |

x | m mm |

De mm |

z | Normalizing Z 104N |

Quenching T 104N |

|||

| 1 | 111.25.500 | 602 | 398 | 75 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 498 | 502 | 65 | 10 | 60 | 0.5 | 5 | 629 | 123 | 3.7 | 5.2 | 80 |

| 112.25.500 | 6 | 628.8 | 102 | 4.5 | 6.2 | ||||||||||||||||||

| 2 | 111.25.560 | 662 | 458 | 75 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 558 | 562 | 65 | 10 | 60 | 0.5 | 5 | 689 | 135 | 3.7 | 5.2 | 90 |

| 112.25.560 | 6 | 688.8 | 112 | 4.5 | 6.2 | ||||||||||||||||||

| 3 | 111.25.630 | 732 | 528 | 75 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 628 | 632 | 65 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 4.5 | 6.2 | 100 |

| 112.25.630 | 8 | 774.4 | 94 | 6 | 8.3 | ||||||||||||||||||

| 4 | 111.25.710 | 812 | 608 | 75 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 708 | 712 | 65 | 10 | 60 | 0.5 | 6 | 850.8 | 139 | 4.5 | 6.2 | 110 |

| 112.25.710 | 8 | 854.4 | 104 | 6 | 8.3 | ||||||||||||||||||

| 5 | 111.28.800 | 922 | 678 | 82 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 798 | 802 | 72 | 10 | 65 | 0.5 | 8 | 966.4 | 118 | 6.5 | 9.1 | 170 |

| 112.28.800 | 10 | 968 | 94 | 8.1 | 11.4 | ||||||||||||||||||

| 6 | 111.28.900 | 1022 | 778 | 82 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 898 | 902 | 72 | 10 | 65 | 0.5 | 8 | 1062.4 | 130 | 6.5 | 9.1 | 190 |

| 112.28.900 | 10 | 1068 | 104 | 8.1 | 11.4 | ||||||||||||||||||

| 7 | 111.28.1000 | 1122 | 878 | 82 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 998 | 1002 | 72 | 10 | 65 | 0.5 | 10 | 1188 | 116 | 8.1 | 11.4 | 210 |

| 112.28.1000 | 12 | 1185.6 | 96 | 9.7 | 13.6 | ||||||||||||||||||

| 8 | 111.28.1120 | 1242 | 998 | 82 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1118 | 1122 | 72 | 10 | 65 | 0.5 | 10 | 1298 | 127 | 8.1 | 11.4 | 230 |

| 112.28.1120 | 12 | 1305.6 | 106 | 9.7 | 13.6 | ||||||||||||||||||

| 9 | 111.32.1250 | 1390 | 1110 | 91 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1248 | 1252 | 81 | 10 | 75 | 0.5 | 12 | 1449.6 | 118 | 11.3 | 15.7 | 350 |

| 112.32.1250 | 14 | 1453.2 | 101 | 13.2 | 18.2 | ||||||||||||||||||

| 10 | 111.32.1250 | 1540 | 1260 | 91 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1398 | 1402 | 81 | 10 | 75 | 0.5 | 12 | 1605.6 | 131 | 11.3 | 15.7 | 400 |

| 112.32.1400 | 14 | 1607.2 | 112 | 13.2 | 18.2 | ||||||||||||||||||

| 11 | 111.32.1600 | 1740 | 1460 | 91 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1598 | 1602 | 81 | 10 | 75 | 0.5 | 14 | 1817.2 | 127 | 13.2 | 18.2 | 440 |

| 112.32.1600 | 16 | 1820.8 | 111 | 15.1 | 22.4 | ||||||||||||||||||

| 12 | 111.32.1800 | 1940 | 1660 | 91 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1798 | 1802 | 81 | 10 | 75 | 0.5 | 14 | 2013.2 | 141 | 13.2 | 18.2 | 500 |

| 112.32.1800 | 16 | 2012.8 | 123 | 15.1 | 22.4 | ||||||||||||||||||

| 13 | 111.40.2000 | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 1997 | 2003 | 100 | 12 | 90 | 0.5 | 16 | 2268.8 | 139 | 18.1 | 25 | 900 |

| 112.40.2000 | 18 | 2264.4 | 123 | 20.3 | 28.1 | ||||||||||||||||||

| 14 | 111.40.2240 | 2418 | 2065 | 112 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2237 | 2243 | 100 | 12 | 90 | 0.5 | 16 | 2492.8 | 153 | 18.1 | 25 | 1000 |

| 112.40.2240 | 18 | 2498.4 | 136 | 20.3 | 28.1 | ||||||||||||||||||

| 15 | 111.40.2500 | 2678 | 2325 | 112 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2497 | 2503 | 100 | 12 | 90 | 0.5 | 18 | 2768.4 | 151 | 20.3 | 28.1 | 1100 |

| 112.40.2500 | 20 | 2776 | 136 | 22.6 | 31.3 | ||||||||||||||||||

| 16 | 111.40.2800 | 2978 | 2625 | 112 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2797 | 2803 | 100 | 12 | 90 | 0.5 | 18 | 3074.4 | 168 | 20.3 | 28.1 | 1250 |

| 112.40.2800 | 20 | 3076 | 151 | 22.6 | 31.3 | ||||||||||||||||||

| 17 | 111.50.3150 | 3376 | 2922 | 134 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3147 | 3153 | 122 | 12 | 110 | 0.5 | 20 | 3476 | 171 | 27.6 | 38.3 | 2150 |

| 112.50.3150 | 22 | 3471.6 | 155 | 30.4 | 42.1 | ||||||||||||||||||

| 18 | 111.50.3550 | 3776 | 3322 | 134 | 3686 | 3414 | 56 | 45 | M42 | 84 | 8 | 3547 | 3553 | 122 | 12 | 110 | 0.5 | 20 | 3876 | 191 | 30.4 | 38.3 | 2470 |

| 112.50.3550 | 22 | 3889.6 | 174 | 30.4 | 42.1 | ||||||||||||||||||

| 19 | 111.50.4000 | 4226 | 3772 | 134 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 3997 | 4003 | 122 | 12 | 110 | 0.5 | 22 | 4329.6 | 194 | 30.4 | 42.1 | 2800 |

| 112.50.4000 | 25 | 4345 | 171 | 34.5 | 47.8 | ||||||||||||||||||

| 20 | 111.50.4500 | 4726 | 4272 | 134 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4497 | 4503 | 122 | 12 | 110 | 0.5 | 22 | 4835.6 | 217 | 30.4 | 42.1 | 3100 |

| 112.50.4500 | 25 | 4845 | 191 | 34.5 | 47.8 | ||||||||||||||||||

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for 2020 Latest Design Excavator Slewing Gear - Single-row cross-roller slewing ring with external gear 111 series – Wanda , The product will supply to all over the world, such as: Algeria, Detroit, UAE, Our company has already have pass the ISO standard and we're fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that merchandise. We hoping that with our good products can bring our customers a great fortune.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.